STL304: All roads lead to Becksvoort

The client doesn’t like color!

The decorative carvings of Kristina Madsen

Video: Kids in the Shop – Shaker Step Stool

Question 1:

From Joe:

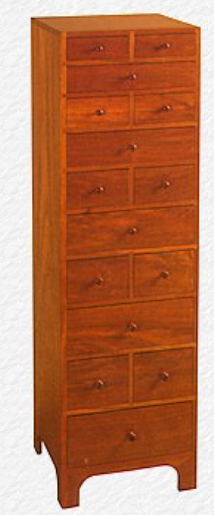

Very shortly, I am going to start making Christian Becksvoort’s icon 15-drawer chest as shown in his book Shaker Inspiration: Five Decades of Fine Craftsmanship. I’ve noticed on this piece, as well as many of the others in FWW that the bottom “rail” has a graceful arch. Becksvoort makes it out of 3 pieces of wood with 45-degree miters.

I would be ever so grateful if you could please find out why he uses three pieces rather than just one piece of wood.

Many thanks for all the help over the years and I look forward to when Anisa has another video with Becksvoort eating strawberries and chatting. That was one of my favorite FWW videos.

Berry Picking with Christian Becksvoort

Build a Bookcase with Doors

Question 2:

From Tom:

I am reworking a bench that belonged to my mother’s cousin who was also a woodworker. This was his primary bench and a lot of furniture was built on it.

When I flipped the bench top over, there were three deep mortises cut across the bench. These mortises are 1 1/2 ” deep and 3/4″ wide in the 2 1/4″ thick top. The top was intended for some other purpose. I have some 2 x 3/4″ hard maple pieces that I intend to cut into 3/4″ blocks to glue into these mortises. I plan to glue them in such a way as to maintain the grain direction. Since the stock I have is only 3/4″ I’ll have to stack them 2 deep to fill the mortise and I plan to stagger the glue joints.

The questions:

I’ve got a lot of end grain to end grain. The glue joint in the bottom of the mortise and between the blocks will be side grain and will be very strong. But the joint between the blocks and the sides of the mortise will all be end grain.

Should I just use Titebond and accept the end grain joint? Switch glues to an epoxy which may work better with end grain. Something else?

Why am I doing this?

I have some hard maple on hand that is sized almost perfectly for the job.

I have the bench apart and the top flipped upside down. If I’m going to do anything about it now is the time.

It seems to me that only having 3/4″ of wood above those mortises constitutes a weak spot. Although the entire top rests on the bench frame (the top stretchers are set so the top rests on them around the perimeter from leg to leg) it isn’t likely to flex and crack. But if it does flex, it’ll be along that line of end-grain joints.

How to Add Strength and Style to Any Slab

High-flying feather veneer

Question 3:

From James:

I started sketching out a wall shelf tool holder to hold my most used tools when I stumbled onto a pic of one that looked just like what I envisioned at The Austin School of Furniture and Design.

There’s got to be a simple answer…

What’s the best way to make 2 shelves side by side at the same height? (Pic attached – too & bottom shelf) Forgive me if my terms are wrong.

Still learning. One center tenon on one shelf, and a double tenon on the other so there are 3 mortises evenly spaced through the center upright? Dowels on each side – probably not as strong, but easier? I’ve always avoided shelves and most furniture does as well. I’m sure it’s that simple but as a newbie, I thought maybe I’m oversimplifying, or there was a trick I do know of. Even though for me that will be stretching my skills.

Ship-inspired wall shelf

Build Bookshelves in a Day

Listener recommendation:

From Declan:

I stumbled across a show on HBOMax recently called “The Craftsman”. The show is about a master craftsman by the name of Eric Holonbeck (SP) a guy in his 70s from Eureka California who does some AMAZING work with equipment that’s older than himself. (Peddle-powered scroll saws, a single pass shaper that makes molded wooden gutters out of 4×4, and lots of other crazy stuff).

It’s kind of scary to watch them in use …. safety is not a big deal …. no safety glasses, no respirators, no saw push tools, and hands are scarily close to the business end of the machine, it’s like working a suspense thriller about woodworking …. well worth the watch.

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.