Q&A: If you have a quality miter gauge, why bother making a wooden sled?

Sometimes buying top quality isn’t enough

When a woodworker spends thousands on a quality table saw with a quality miter gauge or buys a quality aftermarket miter gauge—recommended by Fine Woodworking (“Miter Gauges,” FWW #306)—then why would they go to the trouble of making a wooden sled? Surely technology and manufacturing improvements and standards count for something!

—Konrad Plachta,

Bathurst, Australia

Editor’s reply:

|

|

The need for a crosscut sled in addition to a miter gauge is a subject I’m happy to address. However, it raises the broader topic of just what tools we need in order to accomplish our work, and why they may differ from person to person. Last fall I had the good fortune to participate in a woodworking tour of England hosted by Fine Woodworking (we’re heading back this fall!). At one of our stops we toured the Snowden School of Furniture.

The facilities were outfitted with the aim of instructing students at the highest levels of the craft. Walking through the machine shop, I saw a very nice table saw but no miter gauges or crosscut sleds. When I asked Nick Wright, the school manager, about this, he looked a bit puzzled. He explained that the school’s table saw was set up precisely and used only for rip cuts. He said he’d read about crosscut sleds and such but didn’t find a need for them. It wasn’t that the students didn’t attempt the joinery work I accomplish in my own shop at the table saw; it’s just that they had a different way to go about the tasks.

Crosscuts, for example, are handled at a well-tuned miter saw. This isn’t the only shop I’ve come across without a crosscut sled. I have visited several authors’ shops that lacked crosscut sleds or some other tool that I deemed essential. The consistent theme behind why tools and machines vary from shop to shop seems to be that our processes dictate the tools and machines we own and, conversely, that the tools and machines we own often dictate our processes. It’s something I’ve learned to take into consideration whenever I’m asked about the need to own any specific tool. If it happens to be something I don’t own, there was a time I would have been tempted to answer that because I don’t have it, you don’t need it. Today, I’m more apt to explain how I get by without it, but then to offer reasons why it might be of use to you anyway.

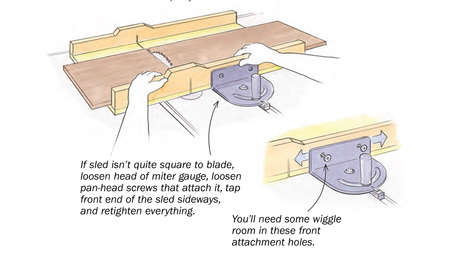

To answer your original question, I can speak only of the reasons why I make use of both miter gauges and crosscut sleds in my shop. In short, I see them as two different tools that serve different functions. With a miter gauge, the stock is in contact with the tabletop, where a sled acts as a carriage to support the stock as it moves across the blade. Because of that, I find that a sled is more versatile; it allows me to perform a number of joinery tasks in addition to the crosscuts that give it its name. I find a miter gauge useful when cutting tenons with a dado blade because I can use a rip fence in conjunction with the gauge as a stop.

Fine Woodworking Recommended Products

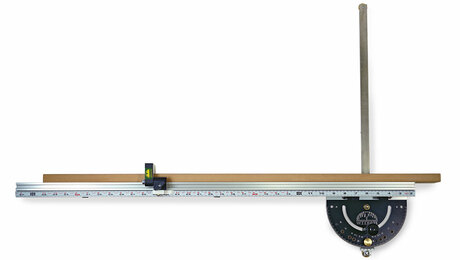

JessEm Mite-R Excel II Miter Gauge

The gauge has a quick and easy method for fitting the guide bar precisely to your tablesaw’s miter slot. This means the gauge can be recalibrated if necessary for continued accuracy. The face of the protractor head can be adjusted square to the table and also square to the guide bar. This ensures accurate cuts, and it, too, can be readjusted if the need arises. The protractor head has stainless-steel knobs and fittings and high-contrast, easy-to-read white numbers and increments.

DeWalt 735X Planer

At high speed, the planer works fast and leaves a smooth surface. But the slower, finish speed produces an almost glass-smooth surface. Knife changes are easy.

Olfa Knife

Comfortable metal handle with a break off blade. A tool for breaking off the blade is built into the handy pocket clip.

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.