Form-fitting outdoor chair – FineWoodworking

This chair is held together with long threaded rods (plus nuts and washers), which not only make assembly easy but also make the chair indestructible. It’s a great example of how sturdy, stylish pieces don’t have to take weeks or months to build.

Because the bolts and nuts can be tightened at any time, they guarantee that the chair will stay as solid as the day you built it, no matter how much the wood shrinks and expands outdoors.

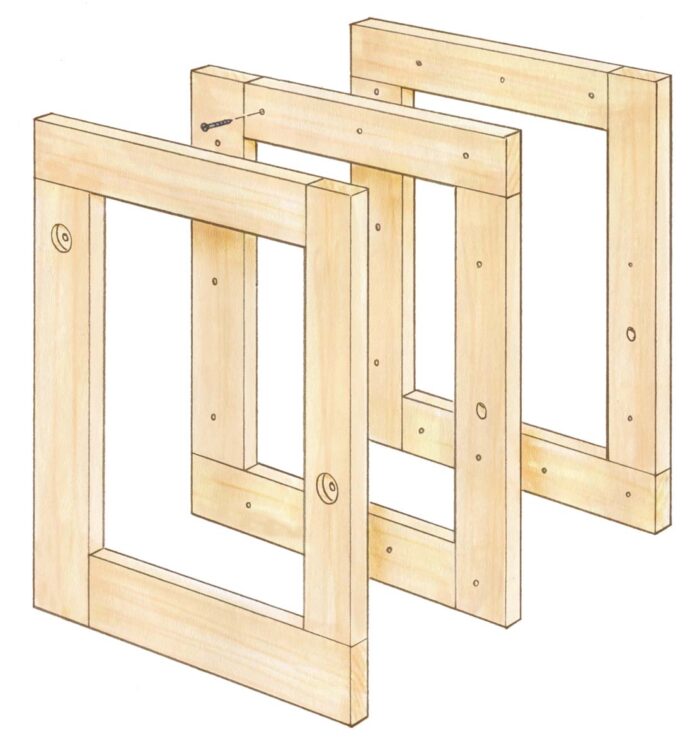

The bolts are also key to the chair’s comfort, passing through the two side frames to align a series of template-routed slats that hug the sitter’s butt and back. Those frames are easy to build, by gluing and screwing together overlapping layers of the same 3⁄4-in.-thick cedar the slats are made of.

I like the way the rows of thin, curved slats catch the eye. While the chair is very comfy as is if you plan to spend hours hanging out or reading in yours, as I sometimes do, try adding flat, firm cushions to the seat and back. The cushions can always come indoors when it rains.

I also designed a simple side table to accompany the chair, assembled in much the same way. The plan for that table is an online extra, available at FineWoodworking.com/309.

Material matters

I love eastern and western red cedar for outdoor projects. It’s light, strong, good-looking, and very resistant to decay. Just be sure to avoid the creamy sapwood, which does not have the same rot resistance as the darker heartwood. Do that and you can skip the finish, letting the wood weather to a nice silvery gray.

I used 3⁄4-in.-thick cedar throughout, but 1-inch-thick material would also work well. Whichever you choose, note that the frames must be made from material of consistent thickness, as must the slats and the circular spacers that divide them. Also, the goal is to have the seat end up around 19 in. to 21 in. wide, so if you use material thicker than 3⁄4 in., you will need fewer slats than the number shown in the drawing.

By the way, since all of the parts are relatively short, I saved a lot of cash by buying cedar cutoffs from a local wood reseller.

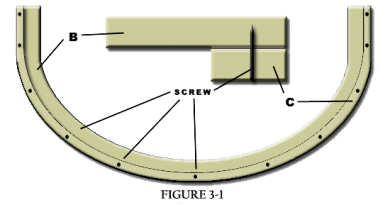

Build in Layers. Use Tightbond III, which is rated for outdoor exposure. Clamp the boards in position, drill, and countersink clearance holes for the 1 1/4″ long screws, and drive them slightly below the surface of the wood. |

Complete the square. Keep working your way around the first two layers. using glue and screws to attach the overlapping boards. The glue will tend to make the top board slide around so clamp it in position before drilling and driving. |

Last Layer. You’re relying on glue alone to hold this third layer in place. Wait a couple of hours for the first two pieces to firm up before adding the next two. Wipe away squeeze out as it happens. |

Template-routing delivers matching slats

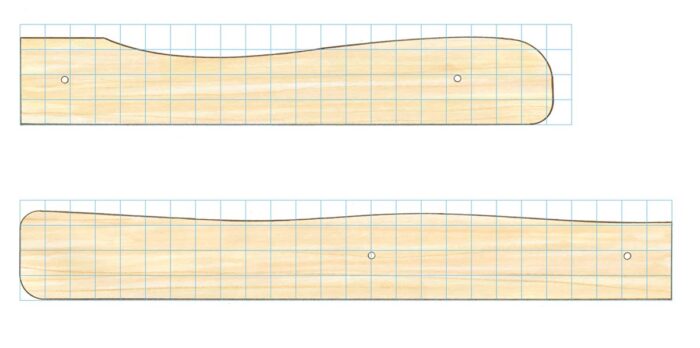

The most time-consuming part of this project is bandsawing and template-routing the big pile of seat and back slats. But this goes pretty quickly once you make a 1⁄4-in. MDF or plywood template for each.

The templates are screwed directly onto each slat for routing, and the screws are placed right where the threaded rods will pass through, leaving perfect starter holes for a larger drill bit later. This ensures that the slats will line up perfectly in the chair.

The template pieces and slat stock start at the same overall length and width, so one will be easy to align with the other. Use the 1⁄4-in. to 1-in.-scale grids on the opposite page to lay out the templates, and try to keep the curves as smooth as possible. I used a compass, a French curve, and a long, bendy stick to draw mine, and smoothed them on my benchtop sander. Don’t forget to mark and drill small holes for the attachment screws.

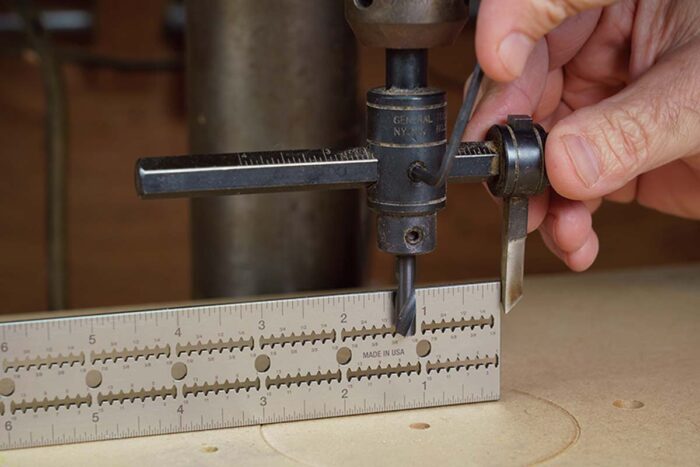

After template-routing all of the slats, use a 3⁄32-in. round over a bit to ease all of the edges. Last, drill and counterbore the slats for the long threaded rods. I started with a 3⁄8-in. twist drill on the drill press, which follows the little screw holes left behind in each slat.

Then I opened up these holes a little with a 25⁄64-in. bit. Note that the holes at the back of the two outermost seat slats need counterbores as well because their long bolts end right there with nuts and washers.

|

|

Fun with circles

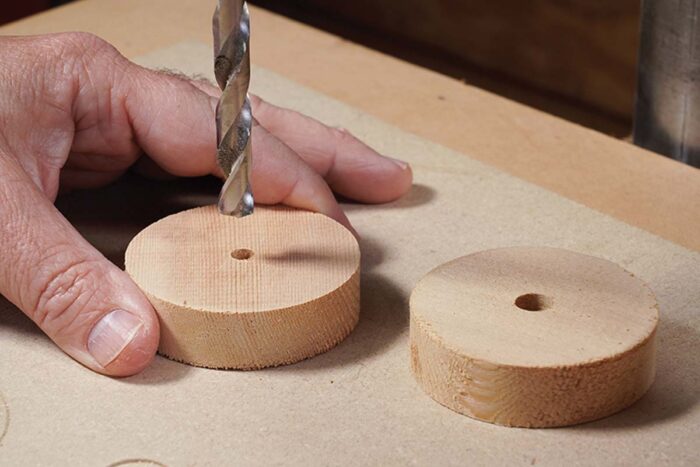

There are spaces between the chair slats, so some sort of filler blocks were needed to keep the spacing even and the chair solid when the bolts were tightened. I thought about making those spacers square, but that would have required that each block be carefully aligned during assembly to create a cohesive look.

Then I remembered my favorite drill-press accessory, the General Tools No. 55 circle cutter. Unlike a hole saw, which is a contractor’s tool, designed to cut rough holes in framing lumber, the General No. 55 cuts very clean holes up to a whopping 7-7⁄8 in. dia., and is infinitely adjustable in its range. Even cooler, when you reverse its cutting bit, the No. 55 will cut smooth circles just as well, which is perfect for this project.

There are some important safety rules, however. First, the circle cutter must be used in a drill press only—never in a handheld drill. Second, the workpiece must be clamped securely. Last, keep your hands well away from the whirling arm.

By the way, the drill bit on the circle cutter makes a hole in the center of each circle. So all I had to do was widen those holes afterward with my 25⁄64-in. bit, and they were ready for the bolts to pass through.

Assembly is quick and easy

The threaded rods come in 3-ft. lengths at most home centers and hardware stores. You’ll need three. When cutting the rod to length, note that they need to end up roughly 1⁄8 in. short at each end so they don’t stick out of their counterbores. I covered the bolt holes with plastic caps (from Amazon), but feel free to omit the caps and embrace the look of exposed hardware.

Attach the sides. Slide the side frames onto the threaded rod, and clamp them against the slat assembly. Thread a nut, with its washer, just barely onto one end of the rod, then tighten the opposite nut, and cut off the excess part of the bolt. Last, re-position the nuts to even them out on the rod. Cap the holes if desired. |

|

Asa Christiana is FWW’s editor-at-large and the author of several books for new and intermediate woodworkers.

Best Outdoor Furniture Projects

Wood Against Weather

Template Routing Basics

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.