Quality tools inspire excellence – FineWoodworking

I am fortunate to serve as a woodworking teacher in a school that champions, through creed and curriculum, the interdependency of mind and hand as a way to cultivate human growth. Our students embark on their tactile journies with soft materials like wax, felt, and yarn—forming, felting, and knitting three-dimensional objects.

Upon reaching the fourth grade, they step into our woodshop to explore wood’s unique properties—its hardness, elasticity, and grain directionality. After acquainting them with saws, chisels, gouges, and rasps, I introduce them to the plane.

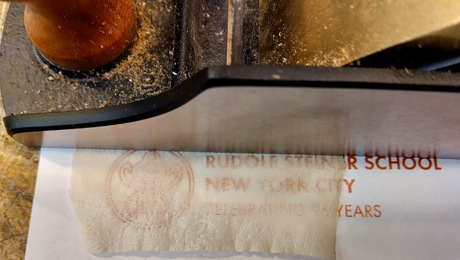

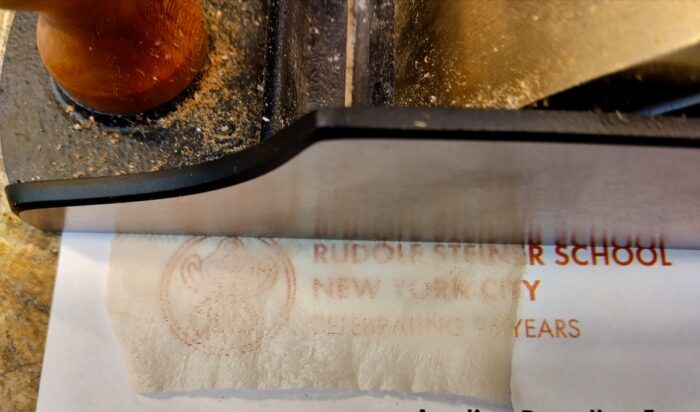

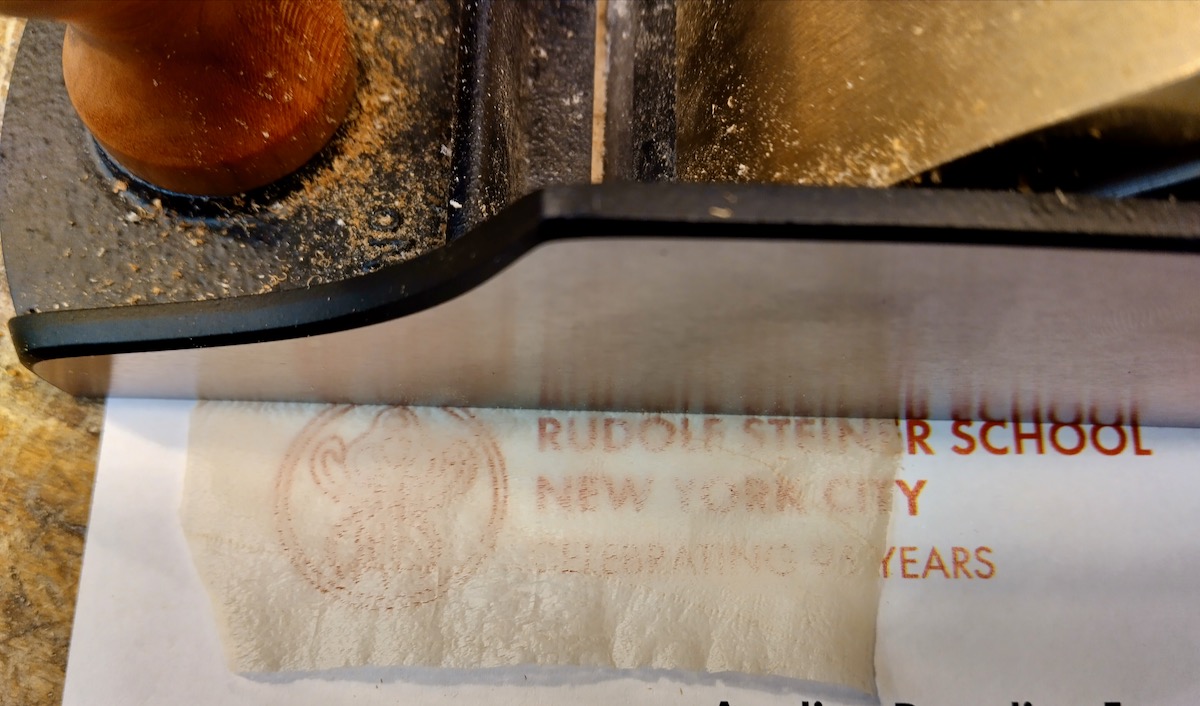

Witnessing a finely tuned tool with a razor-sharp blade effortlessly peeling away thin shavings marks a profound “aha” moment in my students’ immersion into the art of woodworking. The workshop echoes with sounds of astonishment as the lacy strips of hard maple curls emerge from the plane’s throat.

Then, when I unravel a thin curl and let them see, smell, and feel its translucent transparency, they are all in complete awe. This experience is transformative, allowing them to grasp the intrinsic nature of wood—a distinct fibrous material. Unlike the fibers encountered in their earlier handwork classes, wood possesses the unique quality of solidifying its layers, unveiling its true colors only when a keen blade skillfully peels away these layers.

Over the past 90 years, our school’s woodshop has amassed an array of planes, including German planes with their distinct crooked horns, English box-looking planes, and reliable cast-iron tools from both renowned and lesser-known brands.

Our active fleet primarily consists of Record #4 smoothers, an American-made jointer (Stanley #5), a newly introduced Jorgensen #4, a Woodriver #3, and a Veritas Low Angle #5 plane. We also have Taytools #4½ and several block planes, including one from Lie-Nielsen.

Our #5 by Stanley Bailey USA, which I meticulously restored a few years ago (I lapped the sole and repaired the broken handle), has evolved into one of our workshop’s finest tools.

Our planes undergo significant use, particularly during the 8th-grade stool-building and 9th-grade box-making classes. As my students engage with various types of lumber—straight grain, the challenging “crazy grain,” domestic softwood and hardwood, and even scraps of exotic wood—I dedicate a considerable amount of time to sharpening and honing these tools.

While I don’t entrust younger students with the sharpening process, I emphasize the importance of treating the tools with respect and operating them carefully and efficiently.

During my first years in this job, I spent time dressing up our oldies, lapping their soles on abrasive paper glued to a granite plate, tuning their chip breakers, and flattening the backs of each blade. Today, they work great as long as an overenthusiastic student doesn’t attempt to chew off more than the plane can swallow or, in other words, try to project the blade to take insanely thick shavings to speed up the process, only to discover that it’s much harder to plane and most likely will also choke up the mouth.

Last month, I ordered for us the Lie-Nielsen #4½ plane. I intended for that tour de force tool to be used by my most trusted students and to be wielded by me during that magical initiation moment when I showcase to our 4th-grade class the alchemy of transforming wood from a solid block to a soft fabric.

It’s not about the price tag but the thoughtful choice of tools that align with the program’s goals. Craftsmanship is about passion, creativity, and skill, and these values can be instilled regardless of budget constraints. So, whether working with top-tier tools or more budget-friendly alternatives, the key lies in fostering a love for the craft and providing students with the tools they need to succeed.

The Lie-Nielsen #4½ stands as a truly remarkable plane. Minted with the elegance of Japanned ductile cast iron, steel, bronze, and wood—a harmonious symphony of premium materials and craftsmanship—it carries a substantial heft that bestows a commanding presence to every stroke.

Its perfectly milled components, combined with the remarkable feature of being ready for work straight out of the box, elevate it to the pinnacle of tool performance and value. Speaking of value, with a price tag of $360, this tool represents a considerable investment, even for the most affluent woodworking programs.

While having exceptional tools, like the Lie-Nielsen #4½, can undoubtedly enhance the woodworking experience, I understand that not every woodworking program may have the budget for such an undertaking. Nevertheless, I truly think that in every craft and applied arts program, there is value in acquiring a few tools that stand a tier above the rest.

On top of looking elegant, these tools not only outshine their counterparts in performance but also carry the significance of special occasion tableware saved for holidays. They elevate the craft, providing students with a tangible connection to the artistry of woodworking.

Craft, like life, calls for moments of revelation and reverence. Introducing a tool of this caliber has the potential to transform a lesson into a memorable and meaningful experience. If skillfully orchestrated by the teacher, these moments have the power to linger in students’ memories, inspiring a profound appreciation for the art of woodworking.

Moreover, having a special tool that only trustworthy students can use becomes a powerful educational symbol, encouraging students to strive to demonstrate their worthiness. This rare and treasured tool kept separate from the others, is only entrusted to those who have proven themselves in the craft, fostering a sense of accomplishment and responsibility among students. It becomes a worthy investment that significantly impacts pedagogy and shop culture.

The Lie-Nielsen plane, with its exceptional qualities, is such an instrument. Acquiring it not only enhances my program but also contributes to the preservation of a factory that has become a national treasure, reviving and safeguarding the high-end U.S.-made tool-making industry that once dominated the market.

Next time, I will delve into the intricacies of this plane and compare it to another Bedrock-style plane in our workshop.

Bottom feeding in the woodworking world, part 1

Shop Tour: Mario Rodriguez’s Woodshop Classroom and Curriculum

Handplane Fundamentals: Sharpening

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.