Total Quality Management in Woodworking

Errors have a way of multiplying in a woodworking company and errors in one part of an operation can create problems elsewhere leading to more errors, more problems, and so on. Most woodworkers spend a large proportion of their time correcting errors, looking for items, checking for delays, rectifying errors, apologizing to customers, and so on.

TQM – Improving the effectiveness, flexibility, and competitiveness

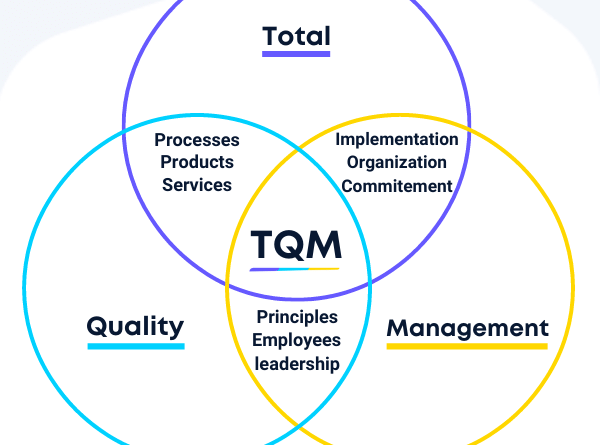

Total Quality Management (TQM) is a way of managing to improve the effectiveness, flexibility, and competitiveness of a woodworking business as a whole. It involves the entire company getting organized in each department, each activity, and each person at various levels. For an organization to be truly effective, every single part of it must work properly together, because every person and every activity affects and in turn is affected by others.

TQM is also a method woodworking companies use to function efficiently by involving everyone in improving the way things are done. The method must be applied throughout an organization so that people from different departments with different priorities and abilities communicate with and help each other. The methods are equally useful in finance, sales, marketing, design, accounts, research, development, purchasing, personnel, and operations.

Some of the most exciting applications of TQM in woodworking have materialized from departments that could see little relevance when first introduced to the concepts.

With training many departments show marked performance improvements. Sales staff have monitored and increased successful sales calls, the office staff has used TQM methods to prevent errors in word processing and improve inputting data to computers, customer service departments have monitored and reduced complaints, and distribution staff has controlled delays and disruption in deliveries.

Traditional QC methods are no longer effective

Organizations that believe that traditional quality control techniques are the only way to overcome quality problems may have to relook at their procedures. Employing additional inspectors, tightening standards, and developing correction, repair, and re-work teams does not promote quality. Traditionally quality has been regarded as the responsibility of the Quality Control (QC) department, and some organizations have not yet recognized that many quality problems originate in the service or administration areas.

In addition to culture and communication woodworkers should consider three important components of TQM:

– A documented quality management system

– Statistical process control (SPC)

– Teamwork for quality improvement

These three components in many ways share the same requirement for an uncompromising commitment to quality. This must start with the most senior management and flow down to the organization. Either SPC or the quality system or both may be used as a spearhead to drive TQM through an organization.

The attention to many aspects of an organization’s operation – from purchasing through to distribution, from data recording to control chart plotting, which is required for a successful introduction of a good quality system or the implementation of SPC will have everyone focusing on the customer/supplier interface, both inside and outside the organization.

A systematic, structured approach to the launch of quality improvement through a balanced introduction of a quality system in a woodworking company, SPC, and teamwork will provide a powerful spearhead with which to improve capability and thereby market share. The importance of the use of SPC and improvements in quality management systems cannot be overemphasized. With increases in automation and the use of advanced manufacturing technologies, the requirement for a total approach to quality is paramount.