Woodworking safely with small parts

The tips in this article sprang from a comment sent to Fine Woodworking’s Shop Talk Live podcast. “Yesterday I was cutting some shims on my bandsaw,” the listener wrote. “The piece I was cutting them from was pretty small, but I thought to myself, ‘I can get another one out of this.’ When my finger was about an inch from the blade, the shim and the offcut got dragged into the throat.

There was a loud bang, and I jerked back. It hurt a lot. After a moment to collect myself, I opened my fist to find my finger intact. The pain came from the wood exploding and hitting it. I fell asleep last night thanking God for the amazing blessing of my hands.”

From handles and pulls to feet, wedges, wheels, drawer stops, and table-attachment tabs, woodworkers manufacture a fair amount of small parts. A lot can go wrong when we do.

While these little parts can be tricky to handle with both hand tools and power tools, hand tools are usually safer, so always consider those as an alternative to power. That said, it’s easier to achieve speed and precision with machines. And that’s where small workpieces are their most dangerous.

The good news is that the solutions are simple. And, as is so often the case in woodworking, safe techniques also yield better results, so best practices are a win-win.

The first solution: Close the throat

The first pitfall in cutting small parts is the one our podcast listener fell into—an opening around the blade that allows a small workpiece or offcut to be pulled into it, damaging it and possibly pulling your fingers with it. Table saws, miter saws, and bandsaws come with large blade slots that accommodate blades of various thicknesses, set at various angles.

Many woodworkers find a way to address this problem on their table saws, knowing that a zero-clearance throat plate will prevent chipping on the bottom edge of all sorts of cuts. But we tend not to address the issue on miter saws and bandsaws, partly because zero-clearance is harder to maintain on those machines, and because it isn’t always necessary.

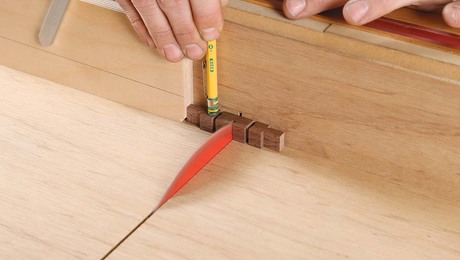

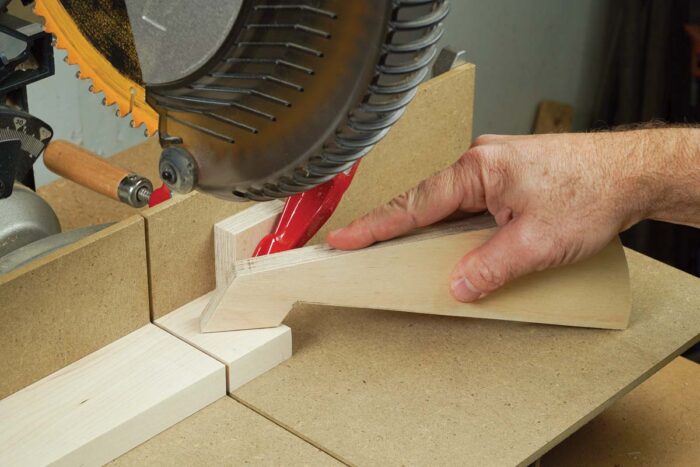

On all three machines, a panel or two of 1⁄4-in.-thick MDF is all you need to create zero clearance around the bit or blade. These tight blade gaps will not only ensure clean cuts and keep small pieces from diving dangerously into a gap, but they will also show you exactly where the blade will cut, so you can align a layout line with the slot, or hook a tape measure on it when setting up a stop.

-Table saw sled

|

|

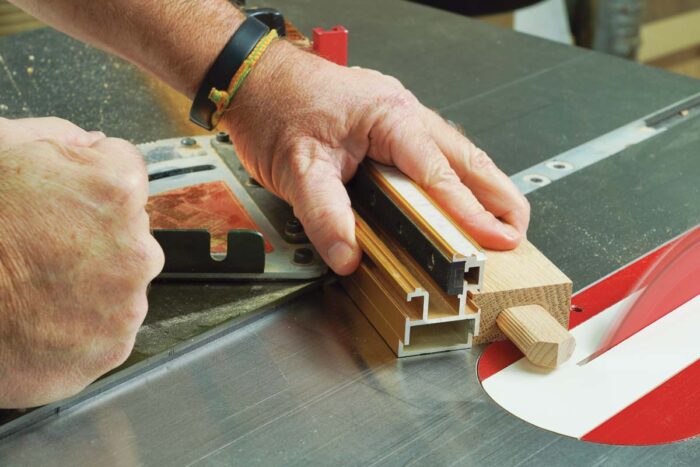

Start with your table-saw sled. Set the blade to the miter angle you want, and use double-stick tape to attach a large piece of 1/4-inch. MDF. Do the same to the fence if needed. Then cut through the MDF (right) to create zero-clearance support around the blade.

-Miter saw

-Bandsaw

|

|

Zero clearance at the bandsaw. Cut partway into a piece of 1/4-inch. MDF, then clamp it in place to create support around the blade.

Wait to turn a long piece into a small one

The second solution is one of the universal principles of safe, effective woodworking. Consider the standard milling process. The reason we joint, plane, and rip parts to thickness and width first—before cutting them to length—is that longer pieces are safer and easier to handle on the jointer, planer, and table saw.

The same goes for small workpieces. The idea here is to do everything you can to a small part (or parts)—including milling, shaping, drilling, etc.—while it is still part of a larger piece. This will make a world of difference when it comes to safety and control, and it’s usually a more efficient way to work.

You’ll be surprised at all the things you can do to a small workpiece before cutting it free from a larger one.

|

|

Same principle as the normal milling process. Milling short parts on a jointer or planer can range from difficult to unsafe. That’s why woodworkers mill parts to thickness and width (above left) before cutting them to length (above right).

|

|

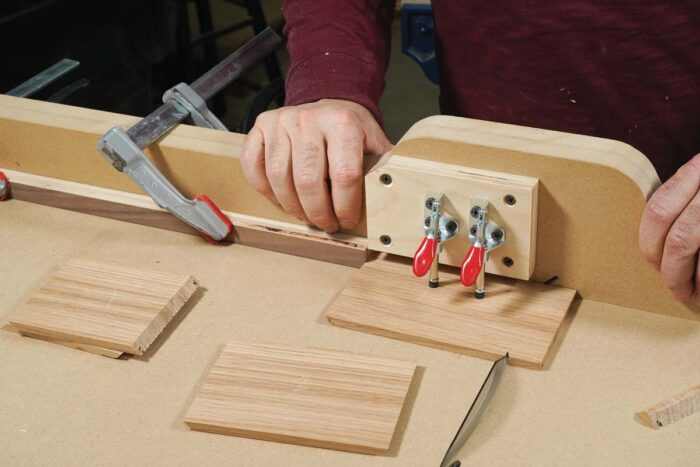

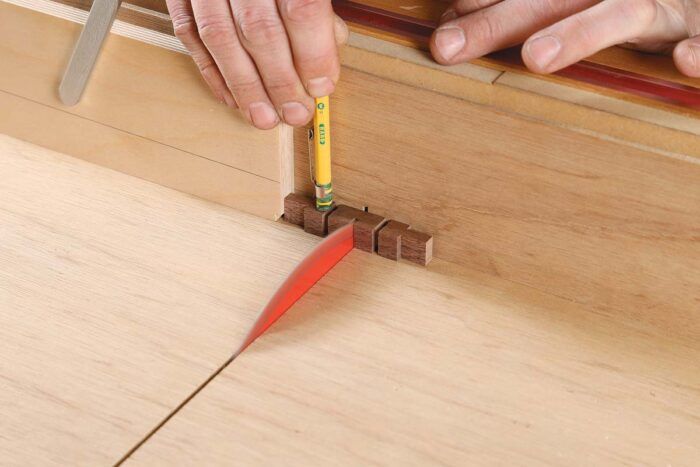

Long parts are safer than short ones. In his Master Class on furniture pulls (FWW #245), Ross Day cut dadoes and slots in a long workpiece, which became a series of small posts (above left and right).

Add a carrier. To cut 60° angles on the ends of Festool Domino tenons, so they could form a threeway joint, FWW contributor Phil Gruppuso inserted the tenons in a long scrap (below). Small workpieces can also be glued to larger scraps for safe cutting or shaping, then cut off afterward.

Cutting, shaping, and drilling small workpieces safely

For very small workpieces, like little mitered moldings, small pins, miter keys, and so on, my favorite cutoff tool is a Japanese handsaw. But when I need even more precision or a bunch of parts cut to the same length, I turn to the table saw or miter saw, adding a stop of some sort.

It’s imperative to control the piece that’s trapped between the blade and the stop. There are a variety of effective ways to control small cutoffs, as shown in the photos.

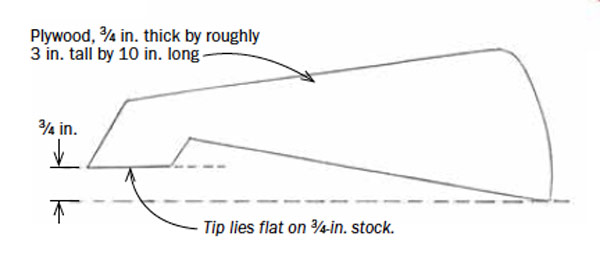

Pivoting Hold-DownTry this handy hold-down. This clever helper from FWW contributing editor Michael Fortune controls small parts safely. Unlike toggle clamps, it requires no setup. This is the general shape of the hold-down. Christiana angles the tip to come down flat on 3⁄4-in. workpieces, but it will hold down thicker and thinner stock too. |

Although there’s a lot of drilling and shaping you can do to small parts before cutting them off a longer piece, there will be times you’ll have to wait until the part is small and unwieldy. Sometimes it’s easiest to hold a small part in a bench vise, allowing you to work on it with a hand tool or sanding block.

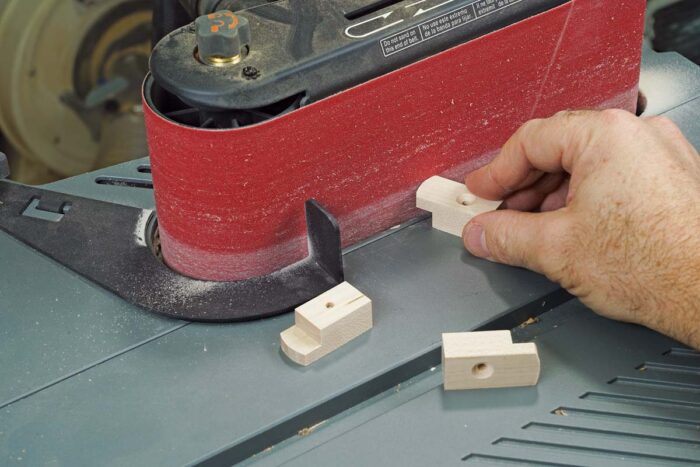

More often than not, however, to finish shaping small parts, I turn to my benchtop sanding unit, which has a belt and a drum. It’s a good option for small parts because the most likely accident is a skin abrasion, which is pretty easy to avoid. When sanding small parts on a disk, belt, or drum, keep the piece on the table if you can. Use a firm grip and a light touch.

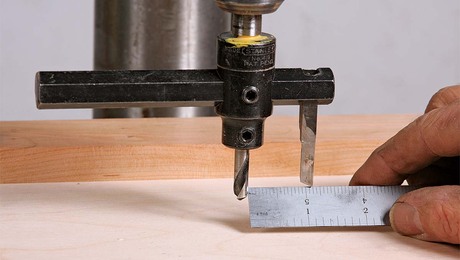

Drilling small parts is less dangerous than shaping them in most cases. I usually do this on the drill press. All you’ll need in most cases is a fence and a stop, with your fingers holding the part in place. But if the drill bit is large, or the part wants to pull upward in a strong way, I secure it in the jaws of a large hand-screw clamp.

There are lots of ways to work small parts safely. These are some of the easiest and best I know.

Asa Christiana is FWW’s editor-at-large.

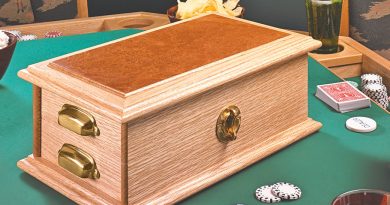

Two Pulls That Pack a Punch

How to Make a Wooden Pendant Pull

Drill Press Tips and Tricks

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.

Download FREE PDF

when you enter your email address below.