End Grain Checks and Cracks in Your Wood

A check is a small crack that occurs in the end grain of a board or logs. These checks can increase in size to form a crack. A crack is usually a grain separation within the fiber. Any piece of timber will check as it dries. This is a natural occurrence but varies between tree species. All will check; some more and some less.

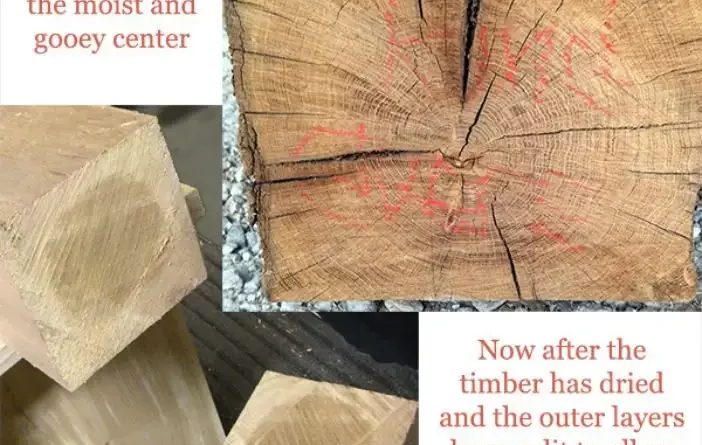

Beginning with a piece green of timber, (greenwood is wet wood) the surface begins to dry; as the wood dries it shrinks; the wood fiber on the outside of the timber dries at a different rate than the inside wood.

As the moisture evaporates from the wood, the outside faster and the inside slower, the exterior wood shrinks, around the interior wood which is wetter and is larger; so the exterior will check as it contracts around the wetter center wood. Left alone these small checks will continue to grow and will render the wood worthless or firewood.

There are several methods to prevent or slow down the checks. To do you have to slow the evaporation process down. One way is to coat the ends of the timber with wax (Anchor Seal is good) this will help but not in all species. The local environment has a lot to do with the drying of the wood. Do you live in a cool moist area or live in a hot dry location?

The timber can be cut into various sizes for future use and then stacked in a cool dry location with good air circulation. There will be some checking and cracking with this method but usually, you can work around them. This type of drying takes longer and requires more room.

The best way to dry wood is to use a kiln. This can be expensive but the recovery of wood from the loss due to checking and cracking is large, and the time required to have dry wood ready to use for your project is a huge benefit. On a small scale, the kilns are easy to build. They require an insulated box of some size, a fan for air circulation, a heat source, and a dehumidifier to remove moisture.

I recently built a small kiln in which I could dry 5 to 6 bowls that I turned from green wood. Most of the bowls take 7 to 10 days in the kiln and I usually place them in a dry place and let them acclimate for about a week. A couple of tech tips. If the dehumidifier removes the moisture too fast the wood will crack, use an off-and-on timer. The moisture meters won’t work.

Weigh the wood each day, as the wood becomes dryer the weight change will slow down. When the weight changes slightly from day to day or ceases to change, the wood is dry. There will always be some amount of warping, so over-cut the wood to be able to remove the warp.

I always like to turn green wood. The small kiln works very well for me.