Finishing the Blank – Step 5 in My Pen Making

Finishing the Blank

Finishing the pen blank is the most tedious of the tasks. The process involves sanding and applying the finishes. There are as many finishes as there are pen-makers. Here, I list the common finishes that I use.

Sanding the Blank

Depending on the smoothness of the pen after turning, I select the right sandpaper. When using softer woods, the pen blanks are quite smooth after the last skew cut and I may only use 600-grit to 3,000-grit sandpaper, very lightly to finish the pen. With harder woods and acrylics, I tend to start with courser grits but finish with the same grit sandpaper.

In each case, I stop the lathe to inspect the surface of the blank before sanding and start with the proper sandpaper. After each sanding, I also stop the lathe and sand the blank along the grain. This helps remove the “lines” due to the lathe.

With some wood, I use sanding sealer before the last sand for a better finish.

Finishing the Blank

There are several ways of finishing the blanks, after sanding. I am continually trying new ways, particularly as some folk prefer satin (and not gloss) finishes. Some of my customers have asked for a “rough” finish! I use the lathe for all finishing processes. After sanding and before finishing, I clean the blanks with alcohol to remove any dust and other foreign matter that will cause problems. Below are four of the common finishing techniques that I use.

- Apply several coats of wax (EEE-Ultra Shine) and at least two coats of friction polish (Shellawax Cream). Both products are Australian-made products and give a shiny finish, or

- Apply multiple layers (up to 10 coats, depending on the wood) of CA glue (super glue) on the blank. Then I sand the blank with wet (water) micromesh (micromesh is a type of sandpaper) up to 12,000 grit for a high gloss finish, or

- Apply two or three coats of Organic Burnishing wax. Then using sandpaper, sand the wood, leaving a nice satin finish, or

- Acrylic blanks are wet sanded to at least 4,000 grit, sometimes up to 12,000 with micromesh, and finished with a friction polish to give a shiny finish.

I have tried other finishes, like spraying on lacquer and wiping on polyethylene, and beeswax. They all have a unique finish. I am sure that new products will be available from time to time.

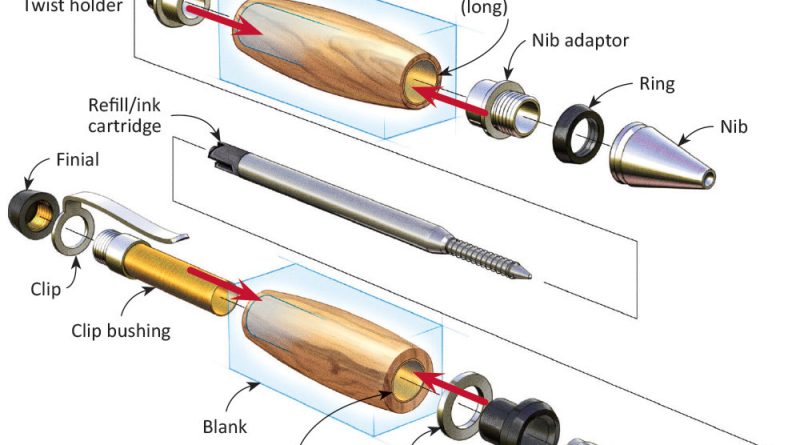

Once the blanks are finished, they are ready for assembly.