How Do I Align the Ryobi BT3000 / BT3100 Rip Fence Rails?

The Ryobi table saw rip fence rails are rather unique in that they are designed to be moved quite easily. The problem is that most likely when they are moved any fine-tuning alignment that was done is lost. Most likely they will be out of alignment once they have been repositioned. My recommendation is to set the rails where you want them, align them, and then never move them again.

Rip fence rail alignment is crucial to the overall alignment of the table saw. The rip fence and the sliding miter table depend on the rip fence rails to be properly aligned.

What are we trying to accomplish?

The rails are a uniform depth below the table saw top.

The rails are parallel to each other.

The rails are level with each other.

When they are out of alignment, what effect does it have?

The sliding miter table should be 90 degrees to the table saw blade. When the rails are out of alignment, the sliding miter table’s angle to the table saw blade will be either greater than 90 degrees or less than 90 degrees. Either way, when using the sliding miter table the cuts will not be square.

The rip fence will also not be at a 90-degree angle to the table saw base. The result will be stock that is ripped to an angle other than 90 degrees.

Alignment process

Parallel rails

The rails are attached to the table via milled bosses. The rails should be parallel to each other if normal care was taken when the unit was assembled. Use a ruler or tape measure to measure the distance between the rails at several points, far left, middle, and far right. If the rails are not parallel, it will require shimming the rail to get them parallel. It is better to shim the rear rail.

Uniform depth below the tabletop

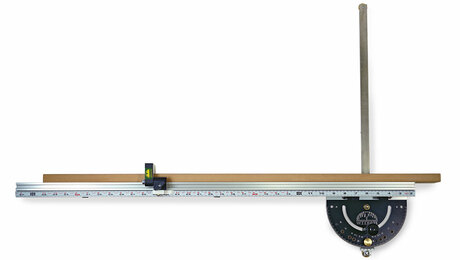

The challenge here is that the main table top is very narrow. It does not provide a very large surface to measure against when checking the depth of the rails. To increase ‘the size of the tabletop, clamp a straight edge to the main table. This will provide a longer span to measure the depth of the rails.

If you have the extension rail kit, bolt it onto the main rails. Then perform the depth alignment. If one of the rails is too low or high, loosen the mounting bolts on the table saw and the extension leg. Adjust the rail’s height from the extension leg adjustment screw.