Quality tools inspire excellence, Part 2: The modern Bedrock comparison

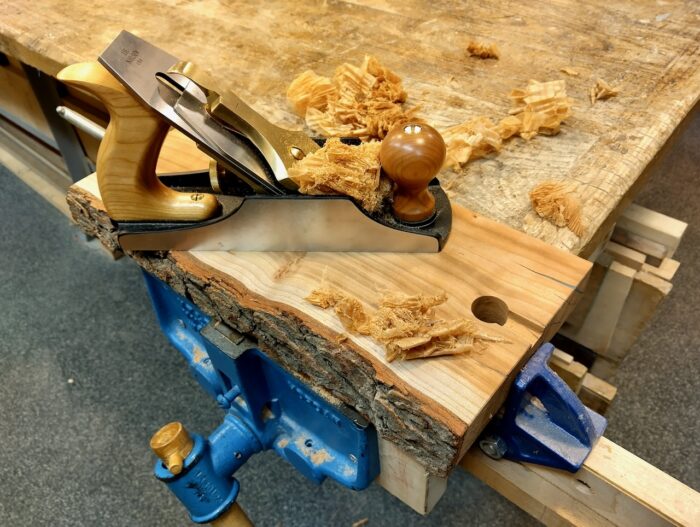

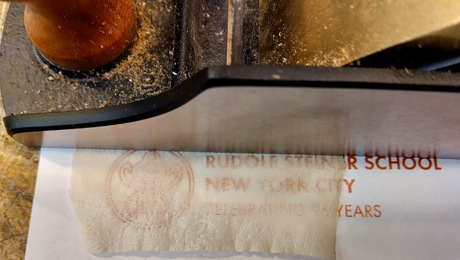

In the preceding segment, I elaborated on the indispensable role of superior tools within my woodworking program. I detailed how finely tuned planes such as the Lie-Nielsen #4-½ can captivate and ignite students’ passions while instilling a deep appreciation for the craft of woodworking. I asserted the Lie-Nielsen as the premier choice among Bedrock-style planes I’ve employed.

In this installment, I will delve into the specifics and juxtapose the Lie-Nielsen Bedrock against two other high-quality Bedrock-style planes: the Clifton and the WoodRiver.

A few words about Bedrock design

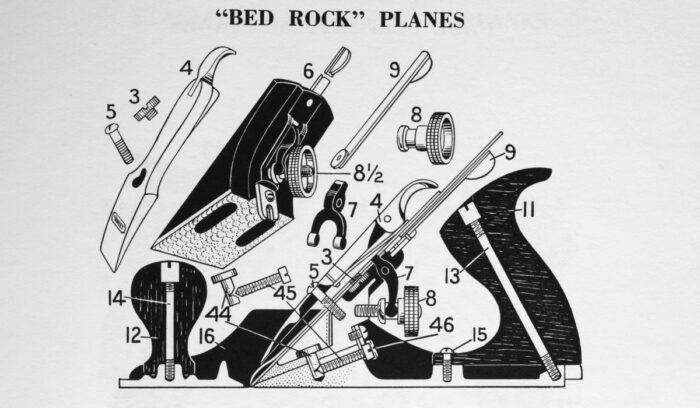

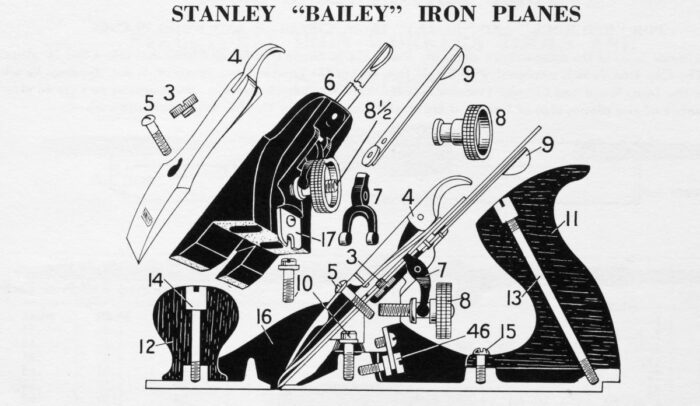

The Stanley Bedrock planes, crafted by Stanley Tools from the late 19th century to the mid-20th century, distinguished themselves as premier woodworking implements cherished for their durability and precision. A hallmark of the Bedrock design was its wedge-shaped frog, facilitating easy adjustment to modify the plane’s mouth width over the ramp-shaped bed.

This innovation empowered users to finely control shaving behavior, a critical factor when working with challenging or figured wood. The plane’s ability to swiftly transition between wide and narrow mouths optimized performance for diverse tasks, from aggressive material removal to delicate surface finishing, thereby mitigating the risk of tearout.

Unlike its predecessors and successors, the Bedrock’s design allowed frog adjustment without removing the cap iron, while its superior geometry minimized chatter, ensuring smoother and more effective planning. These distinctive attributes solidified Stanley Bedrock’s reputation as the epitome of woodworking precision and craftsmanship. You can read more about the history of the Bedrock design on Joel Moskowitz’s blog here.

Enter the modern Bedrock-style plane

In the early 1980s, the landscape began to shift after Thomas Lie-Nielsen embarked on his mission to resurrect and refine the nearly forgotten Bedrock design. The planes they produce retain many features of the original Stanley models but are constructed from superior materials.

These include a ductile cast-iron body resistant to breakage; bronze, brass, and stainless-steel components; and a flawlessly ground and lapped sole. Additionally, Lie-Nielsen equipped the plane with a thick blade and a hefty chip breaker to impart weight and assist in consistent shaving.

A few years after Lie-Nielsen introduced their line of Bedrock planes, the British company Clifton entered the fray, producing their own fine versions. These planes closely resemble Lie-Nielsen’s offerings, although Clifton’s bodies are cast from gray cast iron, which is more prone to breakage if the plane is accidentally dropped onto a hard surface. Subsequently, Woodcraft Co. unveiled their interpretation.

The Chinese-made WoodRiver planes are the third and latest (as of now) Bedrock-inspired planes available to U.S. consumers. The WoodRiver features a ductile body and various stainless-steel parts. While its sole is indeed true and flat, it’s worth noting that, in my experience, it doesn’t quite achieve the same level of flatness as either the Lie-Nielsen or the Clifton planes.

Considering the price differential, with Clifton being slightly pricier than Lie-Nielsen and the fact that Lie-Nielsen’s plane boasts a ductile cast-iron body, my preference among the top Bedrock-style options remains Lie-Nielsen. So, what about WoodRiver?

The WoodRiver’s price point is about two-thirds that of the Lie-Nielsen. Presently, the #4-½ by Lie-Nielsen costs $360, whereas the WoodRiver is priced at $229.99. Thus, does investing in Lie-Nielsen still make sense? The straightforward answer is: if you can afford the Lie-Nielsen, I think you should, and here’s why.

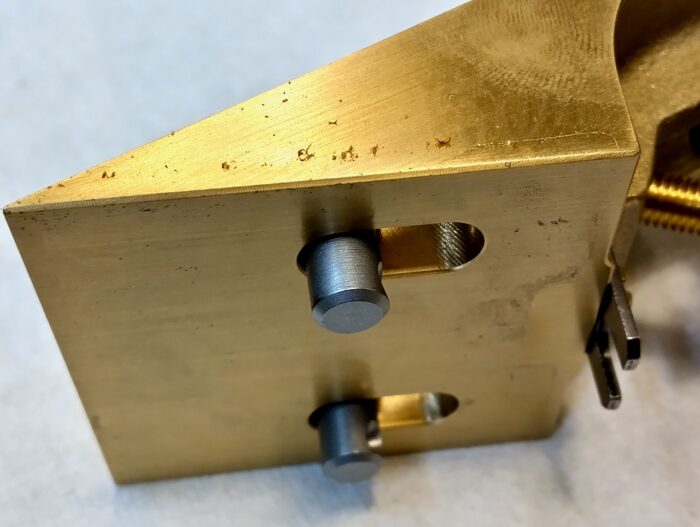

Lie-Nielsen offers a tighter relationship between the bronze frog and the raised rims of its sloped bed. This means adjusting it up or down won’t cause the frog to shift sideways and become misaligned. The Lie-Nielsen frog is better retained in its track compared to the WoodRiver. The WoodRiver exhibits excessive play between the frog and its bed’s rims, so adjusting the frog could potentially misalign it.

|

The WoodRiver’s frog has excessive lateral play compared to the Lie-Nielsen plane. |

Notice how the Lie-Nielsen frog maintains tighter tolerances in its track. |

Moreover, I am a staunch advocate for supporting American-made products and the individuals who diligently uphold our manufacturing traditions and ethos. Without our support, these craftsmen and women may struggle to compete against products manufactured in foreign countries, where labor costs are much lower.

In summation, the journey through the realm of high-end woodworking tools has been a testament to the transformative power of craftsmanship and precision. From the awe-inspiring moments of my students witnessing the delicate dance of wood and steel to the meticulous comparison of top-tier Bedrock-style planes, each experience underscores the profound impact that exceptional tools can have on both teaching and learning.

As we navigate the intricate nuances of plane design and performance, one thing remains clear: Investing in quality not only elevates the craft but also fosters a deeper connection to the artistry of woodworking. With each meticulously crafted tool, we not only shape wood but also mold minds, instilling a lasting appreciation for the beauty of craftsmanship and the pursuit of excellence.

Quality tools inspire excellence

Dumpster diving into Fine Woodworking

Wooden quilts

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.