STL360: Veneer Glue—Stirred, Not Shaken

Veneer then assemble a box, or assemble THEN veneer a box?

From Joe on Discord

I have a bunch of MDF sitting around and some veneer I got at a garage sale, so I was thinking of making a veneered box. What is the typical way to go about it? Assemble the box, then veneer it? Cut the pieces, veneer them, then assemble? Veneer the MDF face, cut the pieces, then veneer the edges?

I can see any of those ways working, but I’m not sure which way usually works out the best.

5 questions about veneering with burl

From TJ on the FWW forum

This is my first attempt at walnut burl veneer, so I have several questions regarding creating a balanced panel for my project.

I’m planning on a small case piece using 1/2″ Baltic birch ply as my substrate. Since I’m unfamiliar with burl I don’t know what to balance it out with on the interior. My questions are;

1. When using a burl, should you use a crossbanding under it? Will such a layer increase stability by the increased glue surface?

2. Since I can’t discern a grain pattern in a burl, is there any need to be concerned about directionality?

3. Do I need to be concerned about the interior veneer’s species or directional placement to ensure balance and a stable panel? Are there better woods to use than others? Is the T&R ratio a factor?

4. Would an MDF-faced ply core be better than the birch?

5. Lastly, would a rigid glue be better to ensure stability?

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page. Join us on our Discord server here.

For the sake of appeasing the robots, here is the show transcript, cleaned up using AI:

Welcome to Shop Talk Live, episode 360. Before we get started, we’ve got a couple of announcements about the format and personnel of the show.

First, I want to let everyone know that Amanda is no longer with Fine Woodworking. We wish her the best, and can’t wait to see what she has in store in the future.

With Amanda no longer with us, we felt the need to bring in a second co-host, and we’ve elevated Vic from frequent co-host status to a true 50% host—someone who’s going to help drive the future of the podcast.

Ben: Hey, Vic.

Vic: Hey, man. How’s it going?

Ben: That’s one way of doing it, huh?

Vic: You betcha.

Ben: When everything went down, I thought, “It’s time for Vic to pull a heavier load around here—take half the episodes—and see what happens.” We’ve been having fun as a duo for a while, so thank you for being a bigger part of the show. You’ve already been a huge part, but now you’re an undeniable force.

Vic: I appreciate it—just being offered the opportunity. I think it’s great.

Ben: We decided we’re going to trade off hosting. You’ll host an episode, then I’ll host an episode.

Vic: Yeah.

Ben: I’m a little concerned that it means we might not end up on the show together, so we need to make sure we do from time to time—because some of the best Shop Talk Lives are when you and I are on it together.

Vic: We can’t keep up that speed the whole time. It’s not fair to the rest of woodworking and the podcast industry. We’re up here and everybody else is just trying to keep up.

Ben: The Olympics are going right now, and there’s an Italian downhill skier—I don’t remember her name—but that’s you and me, Vic.

Vic: Hold on. Let’s get this right. You and I are the Italian woman skier in the Olympics?

Ben: Yes.

Vic: It takes two of us to equal one of those.

Ben: She just won two gold medals, so I don’t know why you think one of us would be capable of doing anything. But yes—we’ll make sure we remain a duo from time to time.

Ben: I’m excited because you have a whole different network of woodworkers than I do, and a whole different perspective on who you want to amplify. You’ve always been a huge part of the show, and I’m thankful you’re taking an even bigger role.

Vic: It’s going to be good.

Ben: Starting with this episode, we’ve got Steve Der-Garabedian on, who has been a friend of Vic’s for many years, an incredible woodworker, and he specializes in veneer work. I like Steve because he makes things approachable. Veneering freaks a lot of people out because they think it’s too hard or too “next level,” but it’s not. It’s approachable. Having Steve on is going to be great, and it opens up a whole new realm of woodworking possibilities—a world where you don’t have to worry about grain direction.

Veneering is like a skill such as dovetailing, but dovetailing doesn’t open up a whole different design universe. Veneering does. Once you learn it and get over that hump, everything changes for you as a woodworker.

We talk a lot in this episode about Steve’s book, Veneering Essentials: Simple Techniques and Practical Projects for Today’s Woodworker. We’ll link to it in the show notes. Vic, why don’t you take us away for your first episode?

Vic introduces Steve

Vic: Sounds good. This is exciting—two-thirds Canadian, one-third American production here. I feel like I should get extra credit because I love Canada.

Ben: And we love you.

Vic: Canada’s probably my favorite country.

Ben: Even though you need snow tires?

Vic: I think about that far too often: “Where would I store snow tires?”

Ben: You could use them where you are, Ben. You guys get a decent amount of snow.

Ben: We just don’t go anywhere. I had a cousin come up from California—late spring—but we had a whiteout for ten minutes. She panicked. I said, “Relax, I’ve got snow tires.” She said, “You’re making that up. There’s no such thing as snow tires.”

Vic: That’s like when we used to invent things like snow snakes for people doing winter training.

Ben: Snow tires aren’t real.

Vic: Steve, you’re known up here in Canada—and all over the world—for your veneering prowess. You even have a book, which is fantastic.

Steve: I do have a book here somewhere.

Vic: You don’t have to show it—most people listen to the podcast. I used to hold things up to the camera, and Ben told me that’s no good. So it’s not show and tell—it’s just tell.

So before we get into questions: why is veneer so important to you?

Why Steve got into veneer

Steve: I get asked that a lot. I went to Rosewood Studio like you did. I researched everything before I went there, and when I saw veneering, I thought, “I’ll take a break during that.” Solid wood or nothing.

Then I got there and was shown how to do it properly. I realized it’s not just cheap stuff that delaminates six months later. When it’s done right, it’s amazing.

One big thing is you eliminate wood movement. Another is: if you want to work with the best woods in the world, you must learn to veneer. I also think we need to be environmentally conscious, and veneering helps with that. I remember hearing Mike talk about the emerald ash borer—how white ash might not be around much longer—and my thought was: get it and turn it into veneer. You extend the resource.

My favorite way is using a vacuum bag. It reminds me of that Popeil chicken roaster: set it and forget it. Same thing with the vacuum press—throw it in there and forget it until eight hours later.

Vacuum pump talk

Ben: Vic, I’m already going to throw you for a loop. You’ve got a legit vacuum pump—what’s the brand?

Vic: It’s VacuPress—the orange smaller one.

Ben: Steve, do you have a VacuPress?

Steve: I do. The VacuPress 300, which I believe is green.

Vic: Question for the audience: do I really need that? Can I not get away with a Harbor Freight vacuum pump for a while?

Steve: I haven’t seen the Harbor Freight one. Princess Auto—whatever you call it. What it comes down to is volume. A top-of-the-line VacuPress could probably run multiple 4×8 bags at once. Mine will comfortably do a 4×8 bag, no issues, and you can vacuum clamp as well.

Smaller pumps—depending on the size of the project and bag—might not evacuate air quickly enough before the glue sets.

Ben: You also run into overheating, right?

Steve: When I was writing my book, I asked the guy who started VacuPress if it was okay to keep the pump running long. He said yes—keep it running as long as you want. If you’re going longer than half a day or a day, take the cover off so it cools better.

Ben: Take its blanket off. I used to have a car like that—pop the hood when you run into 7-Eleven.

Ben: Here was my thinking: glue dries in half an hour. Does it need to be in the bag that long?

Steve: Yes. I like Titebond Cold Press for Veneer. The bottle says minimum 45 minutes up to two hours, but I don’t take anything out of the bag in less than six or seven hours. If it’s bent work, it’s overnight.

The only time I take it out earlier is if it’s a big project and I can’t veneer both sides at the same time. I’ll veneer one side, bag it about 45 minutes, pull it out, veneer the other side, then bag it seven or eight hours.

If you do your pressing at the end of the day—make sure everything’s sealed and not losing air—then go back to the house and let it run overnight.

Ben: One thing that made me happy: Roarockit has a kit that for about $100 does the same thing as a much more expensive press. Your hands and a one-way pump are the vacuum pump. You can even use a shop vac to evacuate most of the air first.

Steve: I let my students do it.

Ben: That’s how he sells electric ones.

Steve: I do have an adapter for my electric pump that lets me do the manual pump. I don’t show them that until the end of the day.

Ben: I even tried one of those big Ziploc vacuum storage bags on a flat press. I wouldn’t trust it for bent work, but it worked perfectly for flat. I was getting about 12 inches of mercury. I like higher than that, but it was enough to get the job done. Those bags are cheap.

If you’re getting into it, Roarockit is accessible. But I keep thinking: for CNC workholding and other reasons, having a vacuum pump in the shop would be nice. Then you see HVAC vacuum pumps for $120 and think, “What’s the difference?”

Steve: Your pump isn’t running the whole time during a six-hour session. If you get a good seal, it comes on maybe once every 20 minutes for about 10 seconds.

Ben: That’s more often than I expected. With Roarockit, are you keeping an eye on it and hand pumping, or letting it roll?

Steve: It depends on the seal. If the butyl tape needs replacing, I’m keeping an eye on it. But I’ve left the house and come back to find a leak and the bag down around 12 or 11 inches of mercury, maybe lower. Not ideal, but it still worked. It doesn’t have to be perfect.

Ben: No, everything needs to be perfect before you start. You need all the gear, all the skill, all the money. And if you make a mistake, just sell it all.

Steve: If it doesn’t work out, take pennies on the dollar and get rid of it.

Question from Joe (Discord): How to veneer an MDF box?

Vic: We’ve got a question from Joe on Discord: “I have a bunch of MDF and veneer from a garage sale, and I was thinking of making a veneered box. What’s the typical way? Assemble the box then veneer it? Cut the pieces, veneer them, then assemble? Veneer the MDF face, cut the pieces, then veneer the edges? I can see all of these working—what works best?”

Steve: You could do all of that. But if you assemble the MDF into a box first, it’ll be much harder to press the veneers. My instinct is to veneer while it’s still flat—in pieces, or one big piece—then cut it and do the joinery to make the box. Any other way makes it hard to press the veneer to the MDF. And you must do both sides.

With MDF, it’s not as bad if you veneer one side and wait a day to do the other. But Baltic birch surprised me: I veneered one side and waited half a day or a day for the other, and it had already warped.

So veneer it before assembling the box.

Ben: When you were writing your book, did you do experiments—just veneer things and see what happens?

Steve: I did. I felt responsible to the reader. I tested different materials and thicknesses: hardboard, MDF up to three-quarter, different thicknesses of Baltic birch, and wiggle wood. I assumed Baltic birch would be the strongest and not warp, but it warped the worst—potato-chipped. MDF was better but eventually did as well.

Another experiment: we’re always told you must use veneer tape because masking tape will leave a hump. I tested it.

Ben: Explain: a hump in what?

Steve: When you joint and join veneer, you might use masking tape on the glue side to hold it together, flip it, put veneer tape on the top, then peel off the masking tape before gluing. We’re told masking tape is too thick to leave there. I found masking tape does leave a hump if left on the glue side—and it also creates a glue-resist area. One layer can show it; two layers definitely do.

As for veneer tape, up to three layers can be okay, but it depends on veneer thickness and species. Three layers can leave a bump. You can sand it out, but you only have so much veneer.

Ben: The key to not sanding through veneer is not to sand through veneer.

Vic: Like Yoda.

Veneer tape basics and process

Ben: Veneer tape is that thin tape—like gum tape—different widths, and versions with holes: two-hole, three-hole, five-hole, nine-hole.

Steve: Machine stitchers use the wide stuff. A machine stitcher is a huge machine—feed in two pieces of veneer and a few seconds later it comes out stitched perfectly.

There’s also threaded versions and other adhesive systems.

Ben: Walk through your process.

Steve: I joint and join two pieces of veneer. On the glue side, I use masking tape across the grain to hold it together—maybe every three or four inches. Then I flip it, wet veneer tape, and do the same across the joint, then one long strip along the joint.

Because veneer tape gets wet and I use too much water, I sandwich the veneer between two pieces of MDF so it doesn’t curl. By the time I prep the bag and glue, I peel off the masking tape from the glue side. The veneer tape is holding it together. Then I glue the substrate and press.

Ben: So veneer tape is never between the substrate and the veneer?

Steve: Usually it’s on the top. But you can use veneer tape on the glue side in certain situations—like cross-laminating a backer veneer when your face veneer grain direction needs to change. In that case I use the veneer tape with holes so there’s glue-to-wood contact through the holes.

The holes can also let you check the seam.

It’s easy to stretch masking tape too much on the initial joint and cause one veneer to slip under the other, which creates a double layer in spots—hard to fix. Being able to see the seam gives assurance you haven’t done that.

Ben: Do you buy holey veneer tape or solid?

Steve: Both. Holey tape is more difficult to remove. Solid peels off easier. Holey isn’t bad—scrape and sand and it’s gone.

Vic: So for Joe: veneer outside and inside first, cut it up, then assemble the box.

Ben: Considerations for joinery on veneered goods?

Steve: Treat it differently. If you’re cutting rabbets like the Ferrazzi method, sharp tools matter. A helical router bit works better. On the table saw, a blade meant for melamine/MDF/veneer works well—more teeth, negative rake (similar to aluminum-cutting blades). It reduces tearout.

A track saw works great because of the splinter guard and the blade action, especially with a blade made for veneer. Lay the track on the veneered surface.

Ben: Steve even cuts and joints veneer with a track saw and a jig. A track saw can be the ultimate veneer jointing machine.

Steve: Even nasty curly ash veneer—track saw does an unbelievable job.

Sponsor read (kept as-is, minus time code)

You love wood. You lovingly choose the wood you use for projects. Then you spend countless hours measuring, cutting, gluing, joining, until your work meets your vision. At Sutherland Wells, they honor your craftsmanship with traditional oil finishes that match the look, feel, and protection that your work deserves. Their small-batch, handcrafted finishes and stains start with the highest quality, cold-pressed, American-grown tung oil, polymerized in their Providence, Rhode Island location, for unmatched quality and consistency. Their low-VOC and VOC-exempt versatile finishes enhance grain, penetrate deeply, resist yellowing, and enhance the natural beauty of wood while providing lasting protection. Sutherland Wells loves wood, too. Take 10% off your first order with code FWW26 and see just how beautiful wood can be.

Forum question from TJ: Walnut burl veneer + balanced panels (5 parts)

Vic: Another question from the forum, from TJ. Five parts—we’ll rapid-fire.

TJ’s Q1: “When using a burl, should you use a crossbanding under it? Will it increase stability by increasing glue surface?”

Steve: I don’t think you need to. It’s extra work you don’t need unless there are potholes in the veneer. Burl often has pinholes and glue can bleed through—but it’ll bleed through whether you crossband or not if you apply more glue. Use veneer glue and mix the solids back in. If it bleeds through, sand it and it’s gone.

Ben: So veneer glue isn’t just about open time—you’re saying there are added solids in Titebond Cold Press?

Steve: Yes. VacuPress has Unibond One, similar: PVA with solids, similar to Titebond Cold Press. Open time/set time is similar to Titebond III.

I used to use Unibond 800 (formaldehyde-based) for longer open time and no cold creep, but I stopped using it. It dried rock solid; squeeze-out was like shards of glass.

TJ’s Q2: “Since I can’t discern grain pattern in burl, do I need to be concerned about directionality?”

Steve: Not really, other than aesthetics. Some burl sheets have straight grain coming out of it. Burl sizes are limited, so on big work you might be jointing multiple pieces and it can look busy. Grain direction is less of a concern. If you’re worried, veneer over something man-made like hardboard or MDF.

Ben: Burl can get garish quickly.

Steve: Less is more.

TJ’s Q3: “Do I need to be concerned about interior veneer species or directional placement to ensure balance and stability? Better woods than others?”

Steve: No. If it will be seen, pick something beautiful. It doesn’t need to be burl on the other side. The rule is: what you do to one side, you must do to the other side.

Ben: Does it have to be equal thickness veneer on both sides?

Steve: In a perfect world, same thickness, but realistically it’s not. It’s really the glue sealing both sides that matters. Thickness doesn’t really come into play in most cases.

TJ’s Q4: “Would an MDF-faced ply core be better than birch?”

Steve: I don’t think it matters. Veneering is putting beautiful wood over ugly wood. With modern glues, bonding isn’t the issue. In my shop I keep it simple: MDF and Baltic birch. You can veneer over steel or glass.

Ben: If you could only have one substrate?

Steve: Quarter-inch MDF.

Ben: Why quarter-inch?

Steve: Because I can stack it and make it thicker if I need to.

Ben: I always heard MDF explodes with water-based glue.

Steve: Don’t put MDF in a cup of water. But I realized: Michael Fortune veneers over MDF, so it’s fine. No grain direction worries. Quarter-inch MDF is the ultimate substrate.

Ben: What about particle core? Cabinetmakers swear it’s flatter than MDF.

Steve: Baltic birch quality has been disappointing the last several years—often warped. MDF is nice and flat. I haven’t gone out of my way to use particle core; I’ve only used it when I needed something heavier. For acoustic reasons I’ve made sound boards with particle core.

Ben: Speaker cabinet material?

Steve: Probably. A lot of speakers use MDF.

TJ’s Q5: “Would a rigid glue be better to ensure stability?”

Steve: No. Modern glues do an amazing job. Just make sure you stir the solids back into the adhesive. You can’t shake it—you must stir it.

Ben: Too many Bonds. For Titebond, you must stir.

Steve: Titebond told me: don’t shake it. Stir the solids back in. I didn’t want to spend my time stirring glue, so I bought cheap fly swatters, cut one down, bent it, chucked it in a drill, and now I stir glue with the drill instead of mixing it like a potion.

Vic: You should sell that to Titebond.

Wrap-up and show notes

Ben: I’m really happy we had Steve on. People still feel tentative about veneering. What I like about Steve is he makes the whole process approachable. In his book he veneers to metal so you can make a veneered magnetic board. It looks incredible, and it’s not difficult.

Any time you learn something new in woodworking, it’s hard until you know. Then it’s like dovetails: people freak out, but they’re easy to cut. Hard to perfect, but functional dovetails come quickly.

Steve’s book doesn’t get too precious—it’s “here’s how you do it,” and then you can take off. Thanks for being here, Steve.

Steve: Thank you. I appreciate the kind words. Veneering can be done cheaply. The first project in the book can be done for less than $30. Even if you don’t buy a vacuum bag, if you have a clothes iron that reaches the cotton setting and some PVA glue, you can veneer with an iron and glue you already have. If you want domestic harmony, buy another iron for $20 and keep your own. Veneering is awesome. It’s not that hard.

Ben: What’s the name of your book?

Steve: Veneering Essentials, by Cedar Lane Press.

Ben: How do you spell your last name?

Steve: Der-Garabedian. D-E-R hyphen G-A-R-A-B-E-D-I-A-N.

Ben: Thanks for being with us, Steve.

Steve: It was awesome. Thank you.

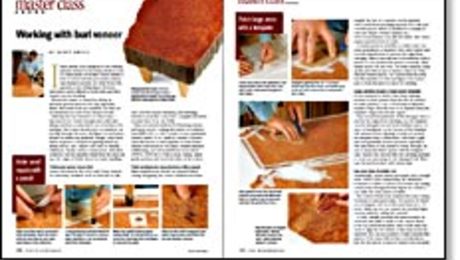

Ben: Before we go, here’s what you’ll find in this week’s show notes: Adrian Farzadi’s Veneered Boxes With a Twist (article and video workshop), Owen’s Plywood and Sheet Goods for the Woodworker, Scott Grove’s Working with Burl Veneer, and Bob Van Dyke’s Introduction to Wood Veneering (including flattening figured and burl veneers). I’ll also include a VacuPress video covering their products and different types of vacuum pumps, including why you don’t want to use a budget pump from a local tool store.

If you’re watching on YouTube, please click the thumbs up. If you’re listening on Apple Podcasts, a five-star review would be awesome. Thanks again to Vic for stepping up. Thank you to Jeff Rose for expertly mixing and assembling everything we’re doing here. We’ll see you in two weeks with another episode.

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.