Testing CBN Grinding Wheels – FineWoodworking

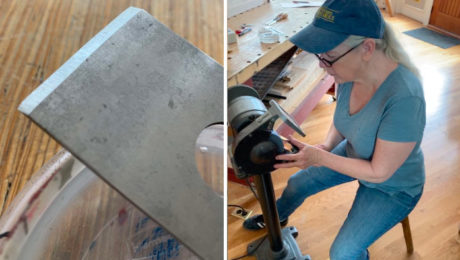

Synopsis: CBN wheels for bench grinders have become popular among woodturners, whose tools tend to be made with high-speed alloys that are tough on traditional wheels. Chris Gochnour wanted to know if CBN wheels could be used to sharpen chisels and plane blades, which are typically made from softer steels.

He was concerned that these softer steels would stick to the CBN wheels, possibly ruining them. In tests using both a traditional grinder and a Tormek grinder, Gochnour found that CBN wheels offered all the benefits of conventional wheels, with none of the downsides.

I have a wood-turning friend who teaches an occasional class at my Salt Lake City workshop. He brings several bench grinders with him each time, which are equipped with CBN wheels. These work beautifully on turning tools, which tend to be made with high-speed alloys that are tough on traditional wheels.

CBN stands for “cubic boron nitride,” an industrial abrasive that’s second only to diamond in hardness. The CBN particles are electroplated onto a steel or aluminum wheel, and they have an almost unlimited lifespan for woodshop use.

Unlike traditional molded grinding wheels, CBN wheels run perfectly true and never have to be dressed, a process that reduces the size and longevity of a traditional wheel. That means you won’t have to adjust your tool rests to accommodate a wheel that gets smaller over time. It also means you don’t have to fuss with wheel dressers.

I had also heard that CBN wheels cut faster than traditional wheels. Perhaps most importantly, they were also reported to run cooler than their old-school counterparts, which can overheat tool edges, removing their hardness and temper and forcing you to grind past the damaged area to get back to hardened steel.

Being primarily a furniture maker rather than a wood turner, I was interested to find out how these new wheels would fare with chisels and plane blades, which tend to use slightly softer steels than turning tools. Those materials include 01 steels, the type used in traditional woodworking tools; tougher A2 steels; and PMV-11, a proprietary powdered steel used exclusively in Veritas tools, sold by Lee Valley.

My worry, however, which was shared by my wood-turning friend and others, was that these slightly softer steels would stick to the CBN wheels, clogging (or “loading”) their abrasives. If there were no way to dress them and expose fresh abrasive grains, as with traditional wheels, the CBN wheels would become less effective, and possibly even be ruined.

Now, based on my testing and that of others, I can confirm that this worry is unfounded, which leaves woodworkers free to enjoy all the benefits of these exciting new wheels.

The bottom line is this: After 35 years as a professional woodworker, I’ll be changing my grinding wheels to CBN.

Sorting through the many options

To help me better understand CBN technology and its capabilities, I collaborated with Ken Rizza, the founder of Wood Turners Wonders (WTW), one of the leading retailers of high-quality CBN wheels. Rizza has several helpful videos on the company’s website (woodturnerswonders.com), which convinced me that these wheels might work just as well on traditional tool steels as they do on more exotic alloys.

CBN wheels are sold in a variety of shapes, sizes, and grits, so my first step was deciding which ones to try. Rizza helped me identify the best bets.

CBN wheels are pricier than traditional grinding wheels. For example, my favorite for a standard bench grinder costs about $160, compared to $50 or $60 for a high-quality traditional wheel.

My goal was to settle on the one wheel that would work best on a common bench grinder, whether slow-speed (roughly 1,725 rpm) or standard (3,450 rpm, more or less). I did that and then did the same for my Tormek grinder.

Testing reveals big benefits

Woodworkers aren’t always aware of this, but traditional molded wheels are often out of the true side-to-side and become somewhat oval with repeated dressing, which makes them out of the true front-to-back as well. This creates vibration in both directions, making grinding rougher and less efficient.

A CBN wheel is machined, on the other hand, and therefore runs true (as true as your grinder does anyway). As a result, the face of a CBN wheel feels like a solid surface in use, and the tool feels very steady in your hand. That also makes grinding more efficient. This is partly why the CBN wheels beat my traditional wheel on raw grinding speed, despite their big differences in grit sizes.

After the speed test, I was leaning toward the 180-grit CBN wheel, so I took the edges that I ground on that wheel to my Waterstones for final honing and found that I could skip the first stone I usually use and jump right to my 1,000-grit stone, with no loss in honing efficiency.

This is a big benefit for hand-tool users. As for burning, it took just eight seconds of continuous grinding on my traditional wheel to begin to darken the steel at the tip of the tool. On the 180-grit CBN wheel, I ground continuously for a minute, with no sign of darkening and burning. The tool became too hot to hold at that point, but there was still no burning present.

This virtually eliminates the main danger associated with traditional grinding wheels. You won’t have to grind with such a feather-light touch on CBN wheels, and you can probably get rid of your little cup of water too, the one you dunk the tip of the tool in every five or 10 seconds to keep it from burning.

During the few months I’ve been using the CBN wheels, I can’t say that I’ve noticed any significant loading of metal between the abrasive grits. I did load up the wheel with Slick-Stick, however, when I applied it too liberally. But it’s easy to scrub off.

A few more tips

Tame the wobble. CBN wheels are machined, not molded like traditional wheels, which helps them run true, avoid vibration, and grind more efficiently. But that only works if your grinder runs true. These nesting washers will self-align to help a CBN wheel run true on a wobbly arbor.

Closing thoughts

Used correctly, a bench grinder offers the fastest way to create a fresh bevel. If you’ve had bad experiences with bench grinders in the past, a CBN wheel will give you all of its benefits without the downsides. And unlike traditional grinding wheels, CBN wheels don’t need to be dressed, saving you even more time.

—Chris Gochnour is a contributing editor to FWW.

Bench Grinder Basics

Grind and get back to work – fast

Tool Test: Bench Grinders for Woodworkers

Fine Woodworking Recommended Products

Norton Water Stones

This kit includes everything you need to sharpen all of your blades, with water stones in four grits and a separate stone to keep them flat.

Wen Diamond Grinding Wheel

The diamond grinding wheel is perfect for flattening grinding wheels before honing chisels and plane blades

Honing Compound

This honing compound is great for loading into a buffing wheel and polishing an assortment of metals.

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.

Download FREE PDF

when you enter your email address below.