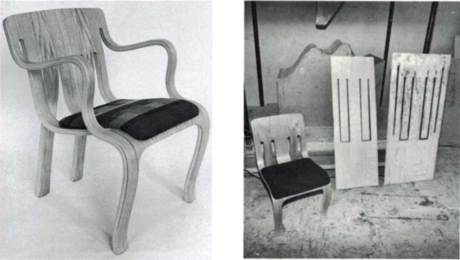

Throwback: Make a Chair from a Sheet of Plywood

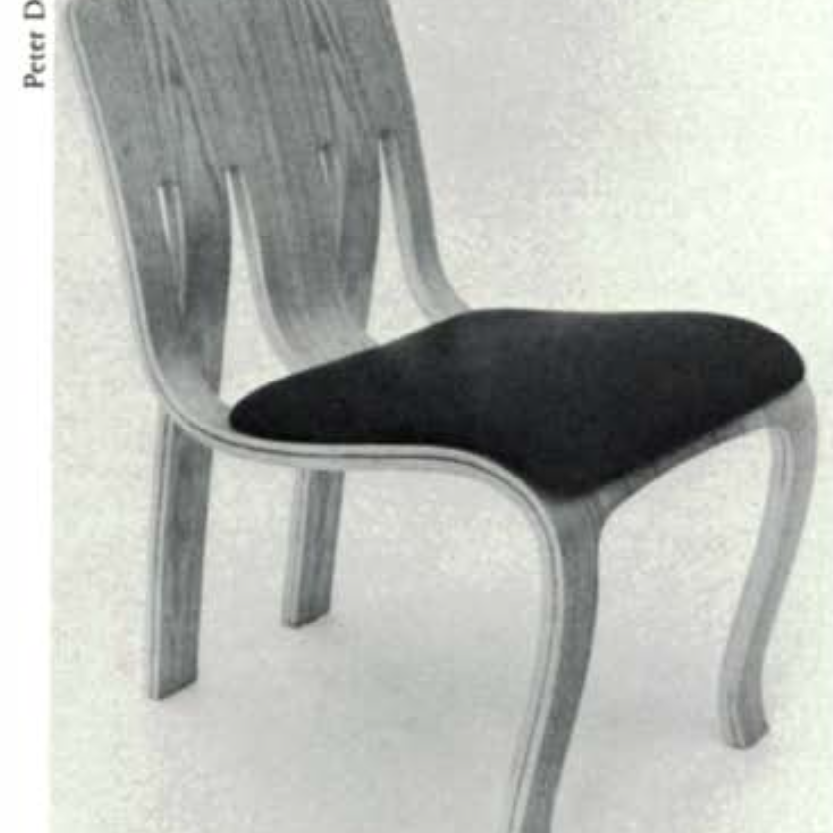

One afternoon a couple of years ago, furniture maker Peter Danko sat in a bar near his shop in Alexandria, Va., slicing up the menu card with a Swiss Army knife. A few slits and folds, and there it was: the one-piece plywood chair he had been musing about ever since touring the Thonet plant in Statesville, N.C.

“I had thought it was so foolish, to cut up and bend all that wood only to glue it together again,” Danko recalls. “After I had made my menu card chair, I put it aside and forgot about it until a few months later when I cut my hand and couldn’t work.

I still thought it would be neat to make a one-piece chair so I fooled around some more. I tried the idea out in Plexiglas, and there was nothing to it. I added an arm and that worked too, so I tried it in wood at 1/4 scale.

“Then I went back to Thonet with my idea, only to learn that most designers have tried to make a one-piece chair. Thonet had even put a couple of staff designers on the problem, but the three-legged chair they came up with wasn’t stable and couldn’t be molded efficiently. They had concluded it was impossible, and seemed to think I was crazy.”

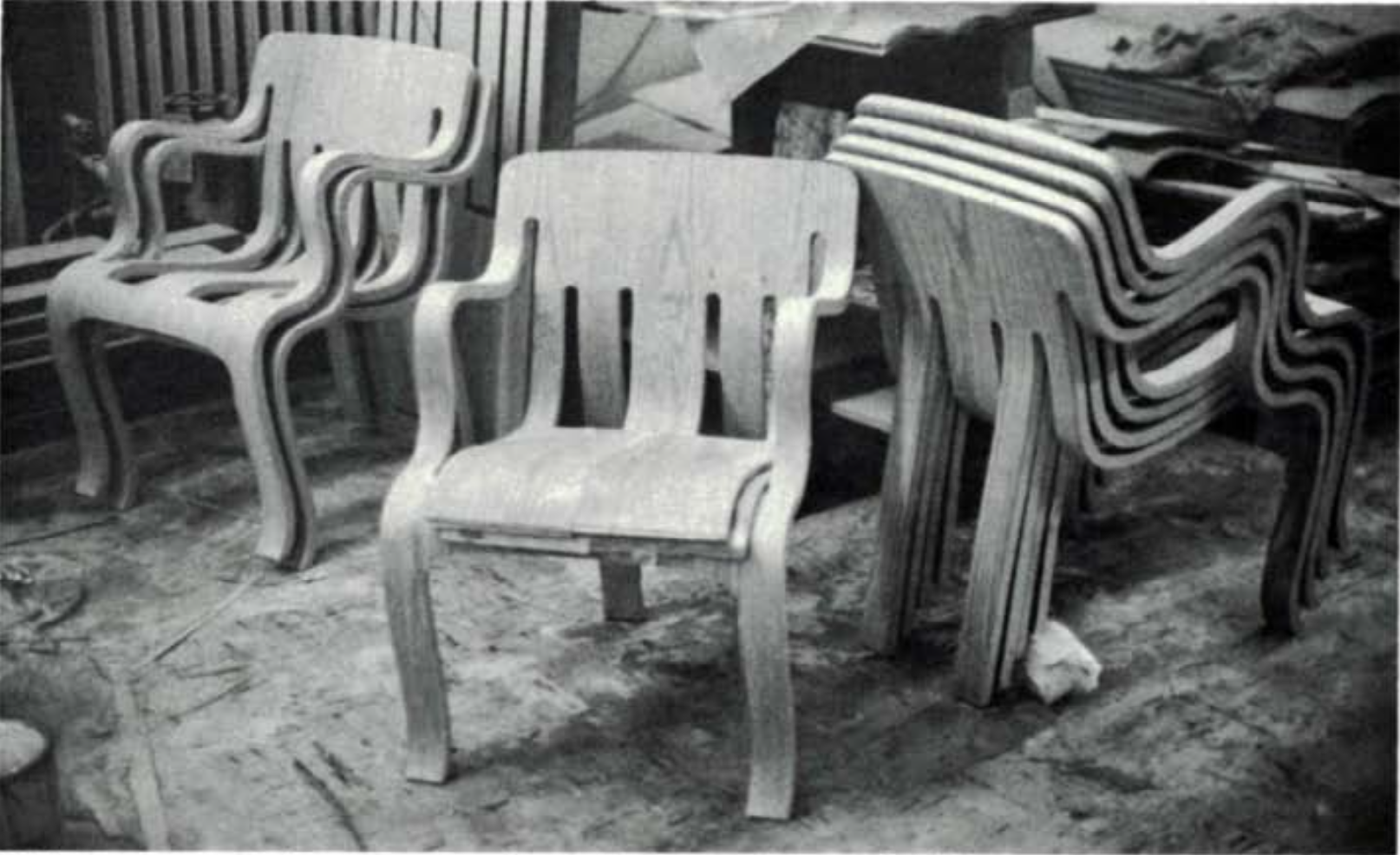

Thonet doesn’t think so anymore, for the firm has contracted with Danko to produce and market his chair in quantity. … But before Thonet would take another look at his chair, Danko had to prove the design by tooling up to manufacture several hundred chairs himself.

He also persuaded the Museum of Modern Art to add one to its study collection, which impressed the Thonet people, and he got the chair into the American Craft Council’s New Handmade Furniture show.

It is a one-piece construction and many arguments have taken place as to how it was cut and bent to the integral design illustrated.”

Danko recalls, “I went around to plywood jobbers, but they also refused to believe it could be done. So I showed my models to my dad, who used to be a pattern maker for the Navy. He thought it was nifty, and he agreed to build the press I’d need if I could come up with $1,800 for materials. I did, and three months later he’d done it.”

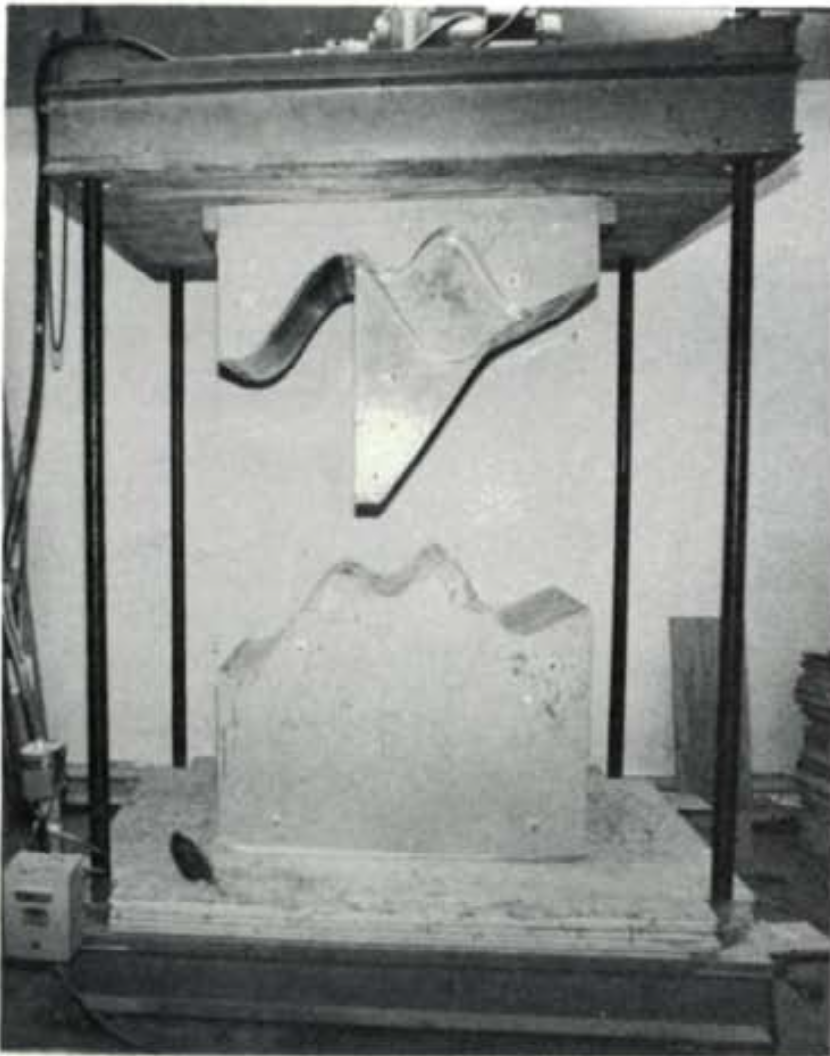

The chair consists of two face veneers sandwiching 10 layers of 1/12-inch. poplar, glued with Franklin laminating glue 6W, for its long open time. It is formed in a two-pan particle-board mold, lined with sheet aluminum, which weighs a half-ton.

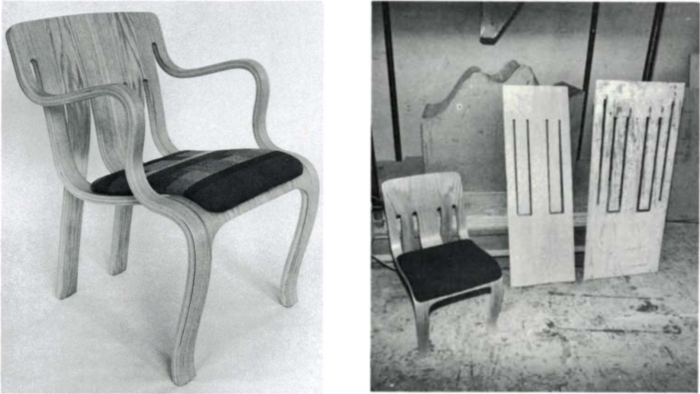

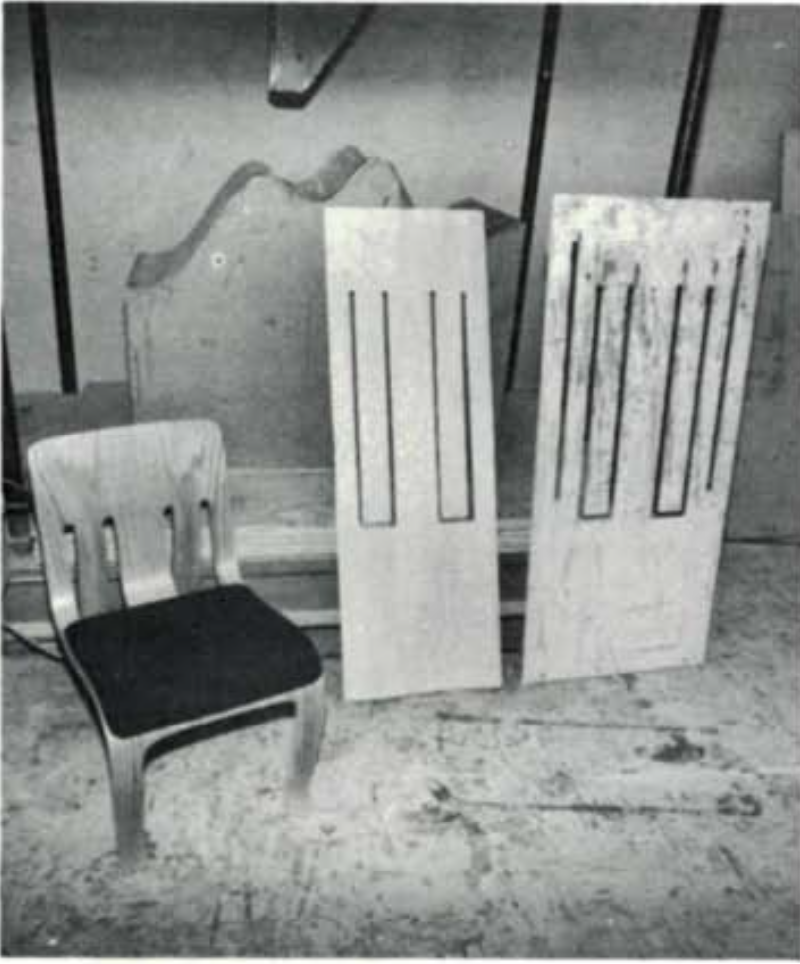

Before pressing, the appropriate slots are template-routed into enough veneers for a batch of eight chairs. The piece later upholstered for the seat is cut out from between the chair’s legs and made only ½ in. thick by putting a piece of waxed paper in the middle of the stack before glue-up.

The wavy line between the halves is, from left to right, the chair’s legs, front, arms, and back. Danko opens the mold by bolting its top half to the upper platen of the press, which was built by his father, George, to his son’s specifications.

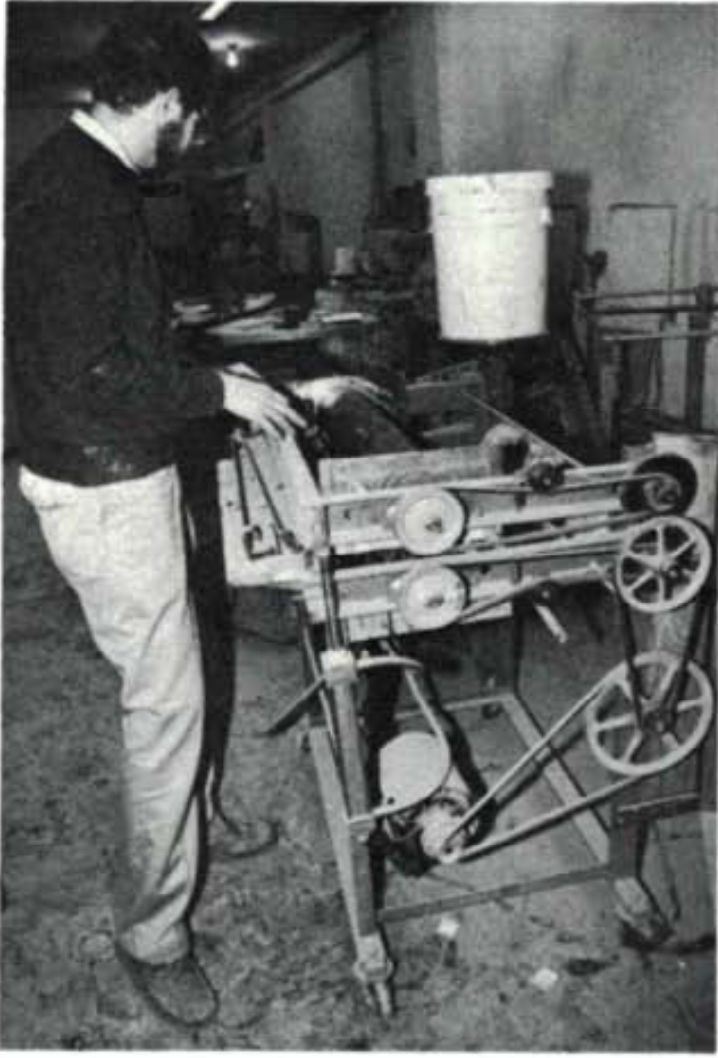

Another Danko invention is a spreader for coating the layers with glue. It’s a contraption with rollers that looks something like an old-fashioned washing machine.

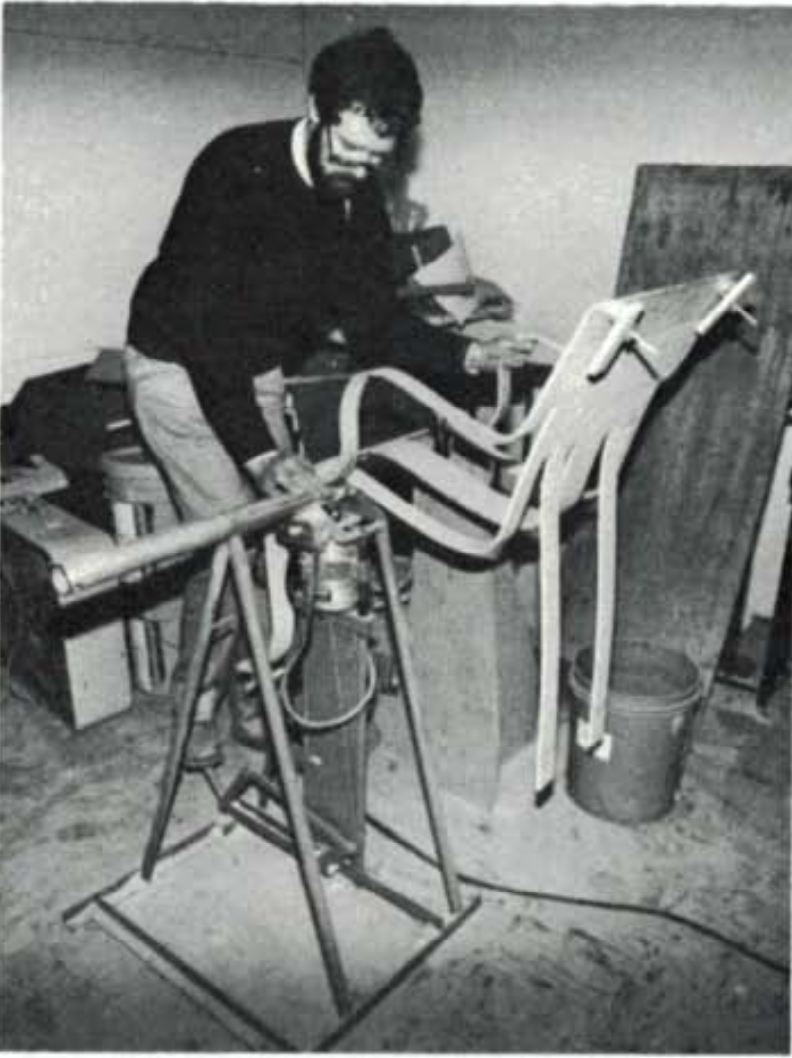

The chair cures for an hour in the press, then it’s trimmed and finished with the aid of yet another of Danko’s father’s devices, a stationary pattern router. This machine consists of a horizontal pipe mounted about thigh-high, with a straight flute router bit protruding through a hole in the top of the pipe.

A template collar is welded to the pipe around the bit opening. Danko clamps a chair-shaped pattern to the rough stack that emerges from the press and runs the whole assembly over the pipe, the template collar guiding the pattern. About 15 minutes per chair and it’s done.

In batches of eight, there’s about 3-1/2 hours of work in each side chair, and about $10 worth of materials. Danko sold the side chairs for $130 each. Thonet’s price won’t be fixed until a hundred chairs come off the line, but a spokesman says it will certainly be lower than Danko’s price.

Although he’s now out of the plywood chair business, Danko still makes sculptured furniture in his shop.

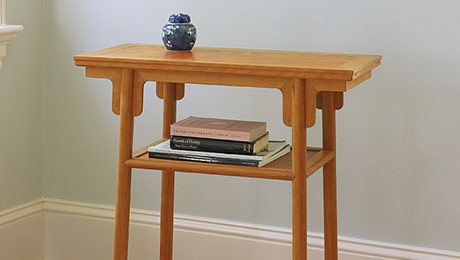

Prevent Springback in Bent Laminations

Safer Glues for Veneer and Bent Laminations

Lamination Bending

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.