What Is the Difference Between Centerless Grinding and Centered Grinding?

Working with power sanders is not a delicate task. It is important to know how to use the machines and understand the best practices for them. When entering the wood or metal working industry, the use of abrasives will become second nature, but there is a learning curve. On the way to mastering sanding and abrasives, you will learn terms and techniques to make you a better wood or metal worker. A pair of terms that are helpful to know: centerless grinding and centered grinding. Continue reading to learn the definitions, details, and differences of both!

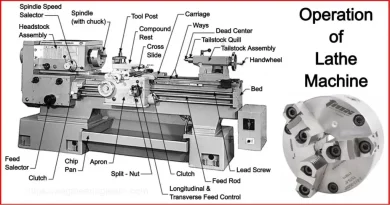

Centered Grinding

Centered grinding simply refers to the traditional method of grinding. The metal or wood piece of placed between two spindles and pushes against a grinding stone. Starting to sound familiar, right? For large-scale uniform grinding using this method, various pieces are placed beneath a set of grinding wheels and pressed against multiple stones to achieve even results.

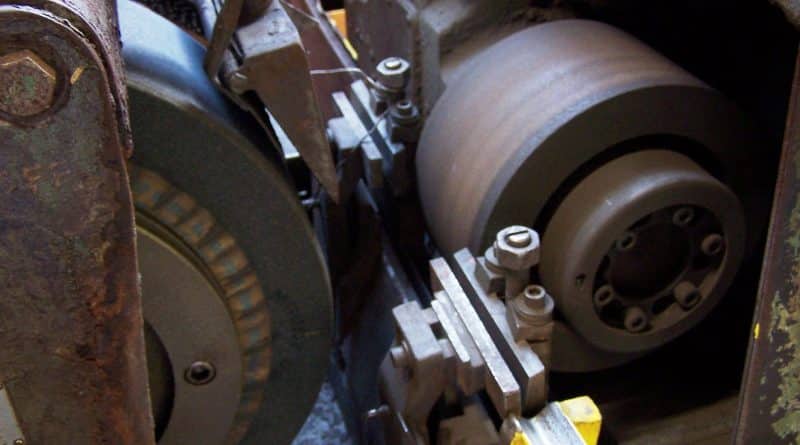

Centerless Grinding

Centerless grinding uses a two-wheel setup, consisting of a drive wheel and a grinding wheel. The metal or wood piece is held into place while the drive wheel pushes it into the grinding wheel. And because centerless grinding does not use spindles like traditional grinding, it is a more efficient means of grinding materials and generally doesn’t even need the assistance of center chucks.

Examples of Centerless Grinding

Manufacturing plants around the world use three prime styles: in-feed, end-feed, and through-feed. Although there are advantages and disadvantages to each style, all three are common techniques used with centerless grinding. The method of grinding used by a manufacturer depends on the style, shape, shave, or cut they desire for their materials and products. While one style may be most apposite for assembly line type grinding or production methods, others are best for more accurate and fine-tuned grinding.

Use Professional Products and Equipment

No matter where you are in your sanding career in terms of competence, it is wise to use the highest quality abrasives, sandpaper, and sanding equipment for all projects to achieve the best possible results. You have to start with the right ingredients to get a good ending result.

Use a trusted and reputable Sandpaper Company to acquire all of your sanding products and materials for centerless grinding and more. They can also answer any questions you have and provide advice for sanding projects. Remember, the better the quality of products and materials, the better quality your results will be. Any veteran sander will tell you that!