Easy to build router table

Synopsis: Designed for a compact router, this small router table will also suit midsize models. Its open design allows for easy clamping to a work surface and easy adjustments to the bit height and removal of the motor. It’s designed so you can customize it to suit your router, your workspace, and your work. The top is melamine for a smooth surface, and the split fence is laminated to keep it stable.

This router table was born because I was sick of devising ad hoc ways of securing my compact router upside down when I wanted to do some quick roundovers on small pieces. A big router table isn’t part of my workflow, but I became sold on the benefits of a small one without all the fancy bells and whistles. So I designed this one, which requires a small amount of materials and doesn’t take much time to build. Although I made it for my compact router, it will also suit midsize models.

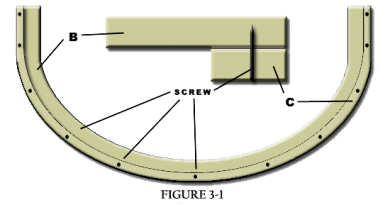

I designed this router table so the sides are solid but the front and back are open. The lower stretchers provide an easy way to clamp the table to a work surface. The open area is sized so I can easily change the bit height or remove the motor from the base; if you’ll use a different router than the one I use, measure yours and adjust the dimensions. Similarly, if you tend to work with larger workpieces or sled-style jigs, you may want to increase the size of the top or the width of the stretchers. Part of the beauty of this design is its adaptability. All the parts go together quickly with screws.

I recommend making the top from melamine for friction-free routing. Plus, its white surface clearly shows pencil lines, which are also easily erased. Just be sure to ease the edges to reduce the risk of those horrible melamine cuts and splinters.

Simple open base

An upgraded top

Although the top could be just a board with a hole drilled in it for the bit and a clamped-on fence, I improved mine with removable inserts for the bit opening and special hardware for a sliding fence.

Begin by locating the router base. I trace the base’s mounting holes onto the top before counterboring and drilling for the screws. If your base’s hole pattern is symmetrical, you can mark these locations on the top face of the tabletop. If the pattern’s not symmetrical, mark the bottom face (since that’s where you’ll mount the router), then drill small through-holes from the bottom to the top. Use these holes to locate your Forstner bit as you counterbore for the screws.

The next step is to create the opening for the bit. Before drilling a through-hole big enough to fit your largest bit, drill a large counterbore to accept the ring-shaped inserts. The inserts shrink the opening when you’re using smaller bits, improving both safety and usability. I make the counterbore’s diameter 1/4 in. larger than the through-hole will be. Since the inserts need to be flush with the top, drill the counterbore precisely to the thickness of your insert stock. Be finicky here. Then cut the through-hole.

For the inserts themselves, I create disks using 1/4-in. melamine or MDF. You want them to fit snugly. Once they fit, drill holes through their centers sized to suit your collection of router bits.

I used to just clamp the fence to the top, but I’ve upgraded to MicroJig’s Matchfit hardware. It works similarly to T-track, but instead of track, it uses dovetail slots you rout into the top and dovetail-shaped nuts that slide in the slots. The depth of the slots must be precise, so home in on your cut in a scrap before routing the top.

Laminated fence with dust collection

The fence is simple but considered. To start, I laminate two long pieces of 3/4-in. plywood, which I prefer because solid wood can warp. Laminating them makes the fence beefier and gives it more reference surface on the bottom, helping it stay square to the tabletop. The fence’s bottom edge needs to be straight and square.

After the glue dries, crosscut the laminated blank into two long pieces and a short one. Screw the short piece to the longer pieces to create the break in the fence for router bits. Use your widest bit to determine that opening.

MATCHFIT Dovetail Hardware Variety Pack – 12 Piece

Create jigs and shop fixtures with the versatile MICROJIG® MATCHFIT Dovetail Hardware. Now it is possible to rout your own tracks, eliminating the need for an aluminum T-Track. This hardware moves through the dovetail tracks below the surface, allowing you to create a variety of jigs that move freely and tighten down anywhere you can rout a groove. Create your own fences, stops, hold-downs, and assembly fixtures.

Price: $13.99 at the time of writing

The cleats for the Matchfit hardware need to line up exactly with the slots on the table. To ensure that they do, first clamp the fence to the table. Install the hardware in the cleats, insert the dovetail nuts in their slots, and slide the cleats up the fence. Then mark their locations on the fence.

As a final step, I wax the fence’s front face so workpieces slide smoothly. Then I rout away.

Setting up and using

Larissa Huff is a woodworker and teacher based in Philadelphia, Pa.

Photos: Barry NM Dima

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.

Download FREE PDF

when you enter your email address below.